| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 18V567

Manufacturer MAC Trailer Mfg., Inc.

Components WHEELS

Potential Number of Units Affected 424

Wheel End may Separate from Axle

If the wheel end separates from the axle, it can increase the risk of a crash.

Summary

MAC Trailer Mfg., Inc. (MAC) is recalling certain 2019 Dump and Waste trailers. The wheel end nut locking device on these trailers may not be properly installed, allowing the wheel end to separate from the axle.

Remedy

MAC will notify owners, and dealers will inspect the locking nut to ensure that it is properly installed, correcting it as necessary, free of charge. The recall is expected to begin in September 2018. Owners may contact MAC customer service at 1-800-795-8454. MAC’s number for this recall is 10-70-001 2018.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Pro-Torq Inspection Procedure

ACTION PLAN: Pro-Torq Retaining Clip (Keeper) Inspection

August 29, 2018 RevC

SAFETY STATEMENT

Always consult with your Certified Safety Administrator prior to any Inspections or Procedures.

AXN Heavy Duty, LLC shall not be held liable for any actions or damage incurred during Inspections or Procedures.

REQUIRED INSPECTION PROCEDURE:

- Remove Hub Cap and discard gasket.

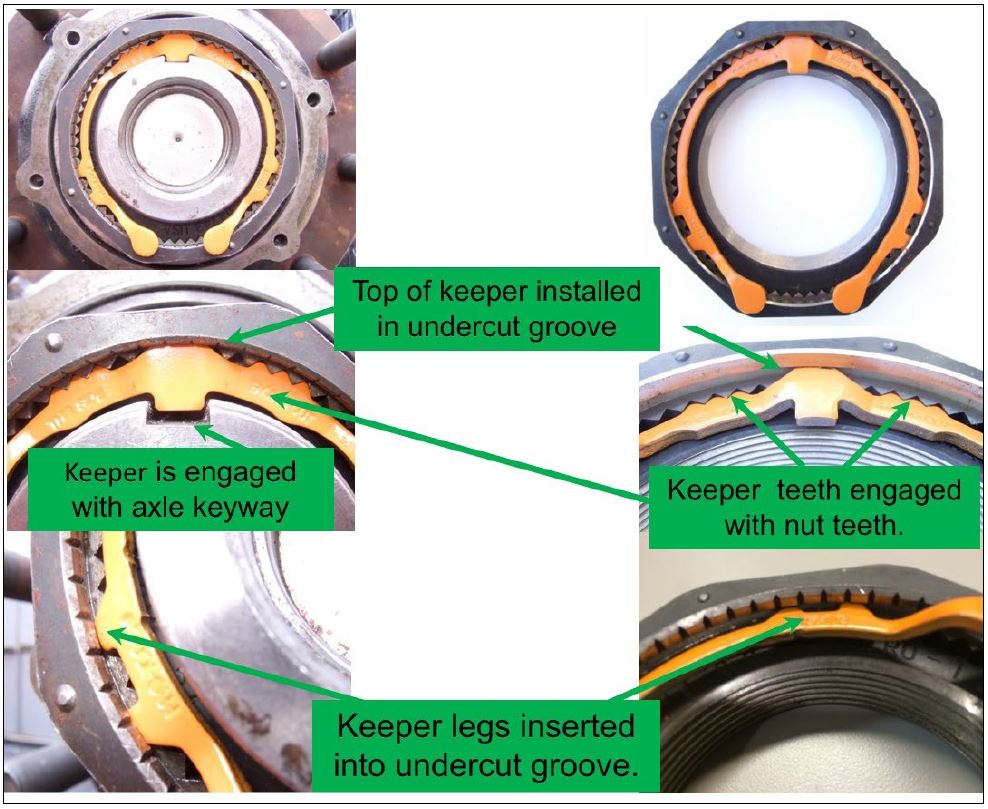

- Visually verify presence of Pro-Torq Retaining Clip (Keeper) (see Figure 1).

- Verify the mating teeth are engaged and the keeper tab and keeper arms are fully seated into the undercut groove in the Pro-Torq Wheel Nut (Figure 1). If all of these conditions are NOT met, see CORRECTIVE ACTIONS

#1 – CORRECTIVE ACTION – if Pro-Torq Keeper is present and mating teeth are engaged properly, but a keeper arm does NOT seem to be engaged in groove:

|

#2 – CORRECTIVE ACTION – if Pro-Torq Keeper is missing or mating teeth are NOT engaged:

|

Figure 1: Pro-Torq Wheel-end Nut and Retaining clip Proper Installation

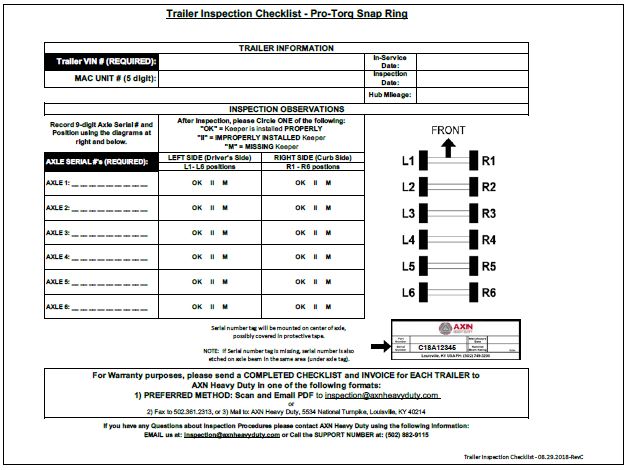

Figure 2: Trailer Inspection Checklist

STEMCO PRO-Torq Instructions

Step 1: Remove the Keeper from the nut

Use a small screwdriver to carefully pry the keeper arm from the undercut groove on each side until the keeper is released.

Step 2:

Thread the nut onto the axle until hand tight against the bearing

Step 3: Seat the Bearing

With hub/drum only:

Using a torque wrench:

A.

(1) Tighten the Nut to 200 ft-lbs. Spin the wheel at least one full rotation.

(2) Tighten the Nut to 200 ft-lbs. Spin the wheel at least one full rotation.

(3) Tighten the nut to 200 ft-lbs. B. Back the nut off until it is loose.

B. Back the nut off until it is loose.

With hub/drum/wheels:

A. Tighten the nut to 200 ft-lbs while the wheel is rotating.

B. Back the nut off until it is loose.

Step 4: Adjust the Bearing

With hub/drum only:

Using a torque wrench:

A.

(1) Tighten the Nut to 100 ft-lbs. Spin the wheel at least one full rotation.

(2) Tighten the Nut to 100 ft-lbs. Spin the wheel at least one full rotation.

(3) Tighten the nut to 100 ft-lbs.

B. Back the nut off one raised face mark.

With hub/drum/wheels:

Using a torque wrench:

A. Tighten the nut to 100 ft-lbs while the wheel is rotating.

B. Back the nut off one raised face mark.

WARNING! Failure to follow this instruction could cause the wheel to come off and cause bodily injury. Failure to back off the nut will cause the bearing to run hot and be damaged.

Step 5: Install the Keeper

ORANGE SIDE FACING OUT

A. Insert the keeper tab into the undercut groove of the nut and engage the keyway tang in the axle keyway. Insert keeper tab with the orange side facing out.

B. Engage the mating teeth.

C. Compress and insert the keeper arms, one at a time, into the undercut groove with a small screwdriver.

NOTE: Recommended practice is to replace the keeper each time the Pro-Torq nut assembly is removed for maintenance purposes.

Step 6:

If the inner tang does not line up with the keyway, back the nut off slightly until it does. Using a small screwdriver, compress and insert the keeper arms, one at a time, into the undercut groove. The orange painted side of the keeper must be facing out

Step 7:

Failure to follow this instruction could cause the wheel to come off and cause bodily injury. Make sure that the keeper tab and keeper arms are fully seated into the undercut groove.

Step 8:

Inspect keyway tang to ensure it does not contact the bottom of the keyway. If contact exists, immediately notify your PRO-TORQ® representative.

Step 9: Acceptable End Play

The dial indicator should be attached to the hub or brake drum with its magnetic base. Adjust the dial indicator so that its plunger is against the end of the spindle with its line of action approximately parallel to the axis of the spindle.

Grasp the wheel or hub assembly at the 3 o’clock and 9 o’clock positions. Push and pull the wheel-end assembly in and out while oscillating the wheel approximately 45 degrees. Stop oscillating the hub so that the dial indicator tip is in the same position as it was before oscillation began. Read the bearing end-play as the total indicator movement.

*Acceptable end-play is .001” – .005”

Please refer to TMC RP 618A “Wheel Bearing Adjustment Procedures”

Agreement for Allowable Standard Repair Times (SRT) for Pro-Torq Inspection Program

The following Terms of Service are effective August 29, 2018:

| BETWEEN: | Owner, Operator, Dealer, Repair Facility (Service Provider) performing the Inspection Procedures |

| AND: | AXN Heavy Duty (Company) 5534 National Turnpike Louisville, KY 40214 |

BILLING AGREEMENT for SRT:

Service Provider is prepared to provide the following professional services to Company.

- A qualified Service Provider will have to precisely follow the INSPECTION PROCEDURE – Pro-Torq Retaining Clips-RevC.pdf.

- For the Inspection Procedure, the Service Provider will charge the allowable rate of:

- Service Provider will fill in all fields on the Trailer Inspection Checklist.pdf and then submit to AXN per the instructions on the checklist, along with the final Service Provider Repair Invoice.

- Bills are payable by Company to Service Provider within 30 days of the receipt date of Invoice.

- Any Questions, or Repairs or Fees OUTSIDE of the scope of Inspection Procedures will need to be discussed with AXN Heavy Duty by emailing inspection@axnheavyduty.com or calling the Support Number at (502) 882-9115.

AXN Heavy Duty

inspection@axnheavyduty.com

502.882.9122

Pro-Torq Retaining Clip (Keeper) Inspection

August 29, 2018 RevC

https://static.nhtsa.gov/odi/rcl/2018/RCRIT-18V567-1217.pdf

Loading...

Loading...

Trailer Inspection Checklist – Pro-Torq Snap Ring

https://static.nhtsa.gov/odi/rcl/2018/RCRIT-18V567-1478.pdf

Loading...

Loading...

Agreement for Allowable Standard Repair Times (SRT) for Pro-Torq Inspection Program

August 29, 2018

https://static.nhtsa.gov/odi/rcl/2018/RMRP-18V567-3480.pdf

Loading...

Loading...

Recall Acknowledgement

September 14, 2018

https://static.nhtsa.gov/odi/rcl/2018/RCAK-18V567-9522.pdf

Loading...

Loading...

- Durable Ratchet Head: Made from Hardened treated Chrome Vanadium steel alloy (Cr-V) Corrosion-Retardant: Satin Finish. Made in Taiwan

- Easy Storage: A sturdy plastic storage case is included. Non-Slip Grip: Knurled handle

- Easy to Read: High Contrast & Dual Range Scale. Accurate: Pre-Calibrated to ± 4%

- Accessories included: 1/2" Drive 5" long Extension Bar and 1/2" Drive to 3/8" Drive Reducer

- Simple and Reliable: “Click” sound tells the preset torque value is reached. Stop applying force when you hear and feel it.

- PRECISION - Ships pre-calibrated to +/- 4% accuracy and ready to use. Include calibration certificate with traceable serial number.

- DURABLE - Reinforced ratchet gear head constructed from hardened, heat treated Chrome Vanadium alloy steel.

- LONG-LASTING - Rust & corrosion protection with our unique and newly invented Electro-Black finish treatment.

- PERFORMANCE - Features an easy-to-read, highlighted yellow print dual-range scale. Identify the markings even in low-light conditions.

- COMFORTABLE - Comes with a reversible ratchet head that drives in both directions and measure torque in a clockwise direction.

- ±3% HIGH PRECISION AND COOL APPEARANCE: 1/2 inch drive torque wrench (10-170ft.-lb/13.6-230.5Nm)has a calibration error range of ±3%, high precision, and comes with a corresponding serial number, which is easy to trace the original data, and you can use it with confidence.Hairich torque wrench not only has superior quality but also has a superior appearance. The classic combination of black and red is fashionable and textured, allowing you to enjoy a visual feast during use.

- PREMIUM MATERIAL AND DURABLE: Experience the ultimate durability and antiskid with the torque wrench. The main body of Hairich torque wrench set is made of chrome vanadium steel alloy, which is more strong and more durable. The head of the inch-pound torque wrench adopts a ratchet design with a reversing device to improve work efficiency. The square knurled handle is made of aluminum titanium alloy, which is ergonomic and comfortable to hold for long-time use.

- DUAL SCALE AND QUICK SETTING: Laser Printed by dual-range(ft-lb and Nm). Our professional torque wrench is easy to read and provides direct unit conversion, When the set torque value is reached, the torque wrench will make an audible and felt click to remind you to stop applying force. Pull down the lock knob and hold it until the torque setting is completed. Release the hand, and the lock knob will automatically rebound back to lock the value.

- ERGONOMIC DESIGN AND POWERFUL: Every design of our industrial torque wrench conforms to ergonomic, easy to handle.72-tooth ratchet, 5° ratcheting arc head, a quick-release button for easy loading and unloading, and an aluminum non-slip handle for excellent grip and control. A recent research review that, 72-tooth ratchets are very professional tooth ratchets, you just only rotate 5 degrees to finish it. Not easy to slip and wear, can be used in small spaces, and is more durable and powerful.

- EASY OPERATION AND SAFETY: Thanks to its bidirectional drive ratchet head, our torque wrench can be measured both clockwise and counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque. Notice: At low Nm settings under 5 Nm the "click" sound can be too light to hear.

- 【High Precision&Quick Reading】: 3/8 torque wrench has high contrast and dual range scale( 5-45 Ft-Lb/6.8-61 Nm),making it clear and easy to read. We have professional torque wrench production technology, and after 20000 tests, the calibration error range of the torque wrench is ± 3%, making it an essential helper for you.

- 【Safe and Reliable Operation】: Equipped with a bidirectional drive ratchet head, torque can be measured clockwise or counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque.

- 【High Quality and Durable Material】: Made of hardened chromium vanadium steel alloy (Cr-V). At the same time, the bottom buckle tail plug adopts a red anodizing process to improve the product's oxidation resistance during use and enhance surface wear resistance. 72 tooth ratchet head, made of chromium molybdenum steel. High quality materials resist corrosion and are durable.

- 【Quick Torque Setting】: Simple and fast torque setting, pull down the locking knob and hold it down to rotate to the torque you need. Release the hand and the locking knob will automatically rebound to lock the torque value. And the designer referred to the appearance of the flashlight handle and designed a non slip and labor-saving knurled handle, making it more comfortable and easy to hold when using.

- 【Easy to Store and Widely Use】: You will receive the 3/8-inch drive click torque wrench with a sturdy plastic shell storage box, which is very delicate and durable. Torque wrench is suitable nuts and bolts on various occasions, such as bike, motorcycle, car spark, and is the best helper for you🎁. 🔔 And we provide 12 months warranty. If you have any questions, please feel free to contact us.

- 【3Pcs Torque Wrench Set】 The calibration error range is ±3%, each torque wrench has a calibration certificate. The 3-in-1 torque wrench set can meet your different needs. Including 1/4 inch 20-240in.lb, 3/8 inch 5-45ft.lb, 1/2 inch 20-160ft.lb.

- 【Safe & Reliable】 When the 1/2 torque wrench reaches the preset torque value, it makes a clear "click" sound, accompanied by an obvious hand vibration that reminds you no longer to apply force, prevent damage caused. 72-tooth reversible ratchet head, it can be used both clockwise and counterclockwise directions.

- 【Quick Release Button】 This 3/8 torque wrench has a quick release button with which accessories can easily be installed and removed, the accessories can grip and is not easy to fall down. It is more convenient to use. The torque wrench is made of CR-MO with a higher hardness.

- 【Easy to Set】First pull down the locking knob and hold it down and then start setting the desired torque value. Release the hand and the locking knob will automatically rebound to lock the torque value. If you do not use, please set the torque key to the minimal torque value.

- 【Widely Use】The torque wrenches can satisfy you in bicycle, motorcycle, car, truck and wheel screws, wheel nuts and in the device installation, electrical engineering, etc. We provide 12 months warranty. If you have any questions, please feel free to contact us.

- PORTABILITY: Torque wrench 1/2 inch drive has a durable case for portability or storage

- ADDED COMFORT: Bi-material handle for comfort and grip of the 1/2 torque wrench

- HASSLE FREE USE: Locking feature adjusts quick and easily for hassle free use

- QUICK IDENTIFICATION: Scales stamped into housing showing inch and metric torque settings

- Meets or Exceeds ASME Specifications

- 🔧【𝐌𝐢𝐥𝐢𝐭𝐚𝐫𝐲-𝐠𝐫𝐚𝐝𝐞 𝐒𝐭𝐞𝐞𝐥】ETOOLAB torque wrench utilizes military-grade steel as its base material, coupled with professional surface rust protection methods tailored to usage habits. While ensuring user comfort, it enhances product strength, wear resistance, and rust resistance. offers a more comfortable experience and a longer lifespan!

- 👍【𝐄𝐚𝐬𝐲-𝐭𝐨-𝐑𝐞𝐚𝐝】The scale of this 1/2 drive torque wrench is laser-engraved, using a black background with white markings. dinamometrica de 1/2 ensures clear and easy readability of the scale, even in sunlight. With a dual-scale design, users can conveniently read torque values in two different units according to their preferences, without the need for conversion!

- ⚙️【±𝟑% 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧 & 𝐒𝐢𝐦𝐩𝐥𝐞 𝐋𝐨𝐜𝐤𝐢𝐧𝐠 𝐑𝐢𝐧𝐠】Our torque wrench 1/2 drive meets the high precision standard of ±3% and comes with a traceable serial certificate. You can use it with confidence! Moreover, its graduation ring is tightly locked, with smaller incremental values, ensuring precise and consistent torque output even after multiple uses. This reduces the hassle of frequent adjustments. It is undoubtedly an excellent tool for your work!

- 🔊【𝐋𝐨𝐮𝐝 𝐂𝐥𝐢𝐜𝐤 𝐒𝐨𝐮𝐧𝐝】This torque wrenches has been upgraded to have a louder "Click" sound. We conducted over 25,000 tests to ensure that each product produces a click sound volume of no less than 45dB when the torque value exceeds 34 lbf·ft. When you hear the distinct click sound, it indicates that the preset torque has been reached, signaling you to stop applying force. You no longer need to worry about damaging your mechanical components.

- 💯【𝐔𝐬𝐞𝐫-𝐅𝐫𝐢𝐞𝐧𝐝𝐥𝐲】Our torque wrench set features a 72-tooth dual-directional ratchet head, allowing for easy operation in both clockwise and counterclockwise directions. It is designed with an adjustable locking ring, making it effortless to adjust the preset torque value. Additionally, it includes a quick-release head design, allowing it to replace the wrench head accessories more easily!

- Includes 1-pc. 3/8 in. drive torque wrench; Storage case; Product manual with torque conversion chart

- Wrench emits a click that can be heard and felt when the preset value is reached

- Permanently marked, high-contrast dual-range scale is easy to read, even in low light

- Reversible ratchet head drives in both directions and measures torque in clockwise direction

- Durable all-steel construction has no plastic parts to break or wear out

- Includes 1-pc. 1/4 in. drive micrometer torque wrench (20-200 in.-lb.) with storage case and product manual; 1-pc. 3/8 in. drive micrometer torque wrench (10-80 ft.-lb.) with storage case and product manual; 1-pc. 1/2 in. drive micrometer torque wrench (25-250 ft.-lb.) with storage case and product manual

- Wrenches emit a click that can be heard and felt when the preset value is reached

- Permanently marked, high-contrast dual-range scale is easy to read, even in low light

- Reversible ratchet heads drive in both directions and measure torque in clockwise direction

- Durable all-steel construction has no plastic parts to break or wear out

- 【PRECISION】 - Ships pre-calibrated to +/- 4% accuracy and ready to use. Include calibration certificate . Before shipping, we take 200 times calibration tests to make sure all wrenches performance well .

- 【DURABLE】 - Reinforced ratchet gear head constructed from hardened, heat treated Chrome Vanadium alloy steel.

- 【 RELIABLE & SAFE】: When small torque wrench set torque value is reached, the wrench will emits slight click sound to remind you to stop applying force to prevent overtorque damage to your items.

- 【LONG-LASTING】 - Rust & corrosion protection with our unique and newly invented Chrome finish treatment.

- 【 DUAL-DIRECTION MEASURES & WIDE USE】: The paddle of the mini torque wrench head can adjust the direction of use at any time,so that the wrench can be used both clockwise and counterclockwise directions. More widely used for Installation equipment, Electrical engineering, bicycle/motorcycle maintenance, Product assembly.With a storage box and an instruction manual.

Last update on 2024-04-11 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.