| “This site contains affiliate links for which OEMDTC may be compensated” |

February 17, 2021 NHTSA CAMPAIGN NUMBER: 21V079000

Loss of Electrical Power May Cause Engine Shutdown

An unexpected engine shutdown can increase the risk of a crash.

NHTSA Campaign Number: 21V079

Manufacturer Navistar, Inc.

Components ELECTRICAL SYSTEM, ENGINE

Potential Number of Units Affected 27,457

Summary

Navistar, Inc. (Navistar) is recalling certain 2018-2021 International LoneStar and 2017-2021 International LT vehicles. The battery ground cable ring terminal at the frame connecting point may break, resulting in a loss of electrical power and unintended engine shutdown without warning.

Remedy

Navistar will notify owners, and dealers will replace the battery ground cable, free of charge. The recall began on April 16, 2021. Owners may contact Navistar customer service at 1-800-448-7825. Navistar’s number for this recall is 21501.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

SERVICE PROCEDURE

21501R2

JUNE 2021

SUBJECT: SAFETY RECALL

Battery Ground Cable on certain International® LT® Series trucks built 18 May 2016 thru 12 January 2021 and LoneStar® Series trucks built 21 July 2017 thru 16 December 2020 with an 08XHK or 08XHL left side under cab Battery Box, a Cummins® X15 or ISX engine, and 6 x 2 or 6 x 4 chassis configuration.

DEFECT DESCRIPTION

The battery ground cable may break at the frame connection resulting in loss of electrical power and unintended engine shut down without warning. Unintended engine shut down without warning may result in a vehicle being stalled on the side of the roadway which could increase the risk of a vehicle crash.

MODELS INVOLVED

This safety recall involves certain International® LT® Series trucks built 18 May 2016 thru 12 January 2021 and LoneStar® Series trucks built 21 July 2017 thru 16 December 2020 with an 08XHK or 08XHL left side under cab Battery Box, Cummins® X15 or ISX engine, and 6 x 2 or 6 x 4 chassis configuration.

REVISION STATEMENT

New changes have been made to parts section. Repair instructions have been revised.

ELIGIBILITY

This procedure applies ONLY to vehicles marked in the International® Service PortalSM with safety recall 21501. Also complete any other open campaigns listed on the Service Portal at this time.

PARTS INFORMATION

NOTE: Do not preorder kits or standalone cables for inventory. Only order additional battery cable kits and/or standalone battery cables after a confirmed appointment has been made and according to vehicle build date.

NOTE: There are two populations of vehicles. The population number / vehicle build date will determine the steps to be performed. All vehicles need to perform Steps 1 through 5 and steps 48 through 54. After Steps 1 through 5 are completed, proceed to the correct service procedures.

- Population 1 – Vehicles built from 18 May 2016 – 10 November 2019

- Population 2 – Vehicles built from 11 November 2019 – 03 March 2021

| Part Number | Part Description | Quantity |

| K2H2212035 | Cable, Battery, Negative 00 Gauge | 1 |

| 3626607C1 | Strap, Cable Lock – 14 inch | 1 |

| 3744063C1 | M10 X 45mm Bolt, Tin Zinc Plated | 1 |

| 3718728C1 | Nut, Special M10 x 1.50 Hexagon, Keps Electrical Ground | 1 |

| 476074C1 | Nut, Battery Terminal 3/8 Inch UNC | 1 |

| VINT21501 | Dielectric Coatings Reapplicant Kit | 1 |

Parts Table 1 – Population 1

NOTE: Only 10 percent (3,308) out of total population of 33,082 will require 8900291R1.

| Part Number | Part Description | Quantity |

| 8900291R91 | Kit, Ground Battery Cable | 1 |

| 3744063C1 | M10 X 45mm Bolt, Tin Zinc Plated | 1 |

| 3718728C1 | Nut Special M10X1.50 Hexagon Keps Electrical Ground | 1 |

| 476074C1 | Nut, Battery Terminal 3/8 Inch UNC | 1 |

| VINT21501 | Dielectric Coatings Reapplicant Kit | 1 |

Parts Table 2 – Population 2

8900291R91 contains the following parts:

| Part Description | Quantity |

| Cable, Battery, Negative 00 Gauge | 1 |

| Clamp, Saddle | 1 |

| Bolt 1/4 Inch X 3/4 Inch | 1 |

| Washer, Lock, 1/4 Inch Reg Steel / ZNC 1/4 Inch | 1 |

| Nut, Hexagon Type 8 1/4 Inch UNC | 1 |

| Extension, Clip | 1 |

| Guide, Brake Hose and Cable Spacer / Swivel Saddle | 3 |

| Strap, Cable Lock | 10 |

Parts Table 3 – 8900291R1 Contents

TOOLS INFORMATION

| Part Number | Tool Description | Quantity |

| N/A | Standard Wire Brush | Source Locally |

| N/A | Small Scraper | Source Locally |

| N/A | Small Paint Brush | Source Locally |

| N/A | Small Metal Container | Source Locally |

SERVICE PROCEDURE

WARNING! To prevent personal injury and / or death, or damage to property, park vehicle on hard flat surface, turn the engine off, set the parking brake and install wheel chocks to prevent the vehicle from moving in both directions.

WARNING! To prevent personal injury and / or death, always wear safe eye protection when performing vehicle maintenance.

WARNING! To prevent personal injury and / or death, or damage to property, keep flames or sparks away from vehicle and do not smoke while servicing the vehicle’s batteries. batteries expel explosive gases.

WARNING! To prevent personal injury and / or death, or damage to property, remove the ground cable from the negative terminal of the battery batteries before disconnecting any electrical components. always connect the ground cable last.

NOTE: There are two populations of vehicles. The population number / vehicle build date will determine the steps to be performed. All vehicles need to perform Steps 1 through 5. After Steps 1 through 5 are completed, proceed to the correct service procedures.

- Park vehicle on flat surface.

- Shift transmission to Park or Neutral and set parking brake.

- Turn vehicle ignition to Key OFF position.

- Install wheel chocks.

- Remove aerodynamic skirt, if necessary, to gain access.

Population 1 – Service Instructions for Vehicles Built 18 May 2016 thru 10 November 2019

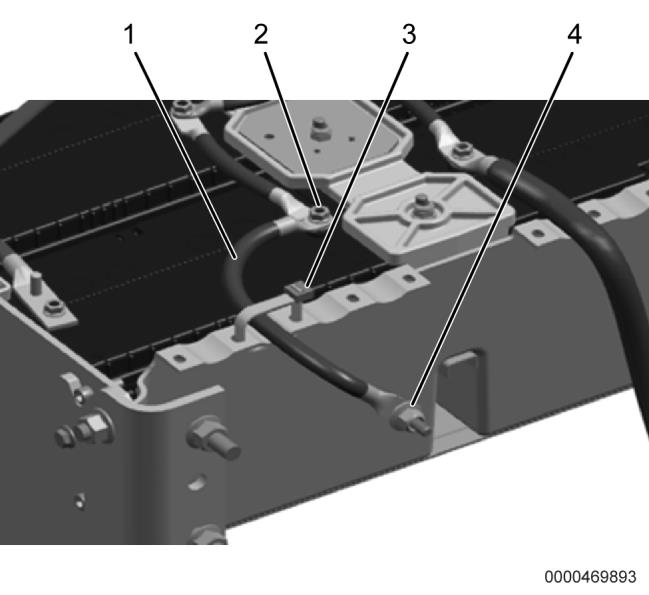

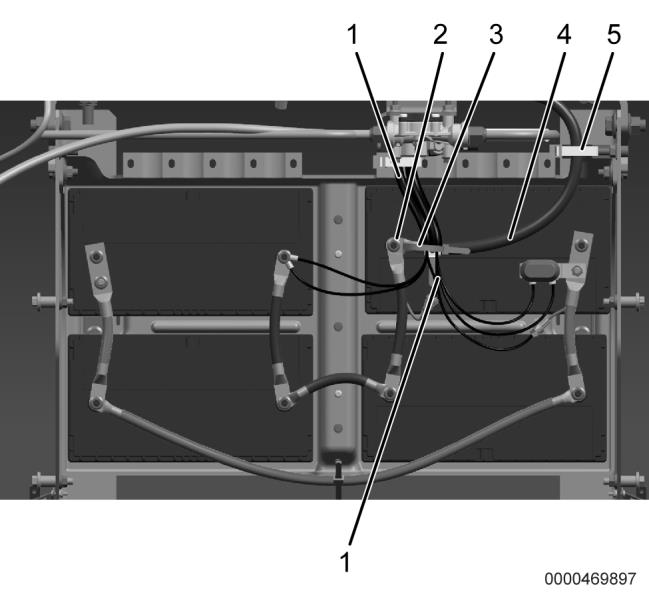

Figure 1. Routing of New Battery Cable for Population 1

-

- Battery ground cable

- Battery stud nut

- Cable tie strap

- Battery cable frame bolt and nut

- Is the truck you are working on built with RED sealant paint on the frame bolt and nut?

a. Yes – continue with Step 8.

b. No – proceed to Step 13.

CAUTION! To prevent damage to property or vehicle components, RED sealant paint must be thoroughly softened and fully removed from bolt and threads. Avoid drip onto unwanted surfaces. DO NOT apply to rubber, wire insulation and the like, only metallic surfaces.

- Shake softener gel container to thoroughly mix contents. Slowly open container.

- Pour needed amount of softener into small metal container. Using paint brush, apply liberally to RED coated threads, nut, and bolt (metal surfaces).

- Let softener sit for 10-15 minutes. Longer set time will yield better results.

- Using scraper, wire brush, and rag, remove as much coating as possible. Second application of softener chemical may be required; use discretion prior to loosening nut and bolt.

- Using abrasive pad or cloth dipped in odorless mineral spirits, remove remaining finish or residues.

- Disconnect battery ground cable at frame. Save bolt and nut for reuse. Discard battery ground cable only.

- Clean negative battery cable connection point on frame.

- Clean battery terminal with wire brush, then clean with electrical contact cleaner and dry with shop air.

- Route new battery ground cable to frame and under all other harnesses that may be in battery box, as shown in Figure 1 .

- Install battery cable frame bolt (Figure 1, Item 4), install ground cable and nut (Figure 1, Item 2). Using torque wrench, tighten cable frame nut to 31 lb-ft (42 N•m).

- Apply RED sealant paint and thoroughly coat frame bolt, bolt threads, nut, battery ground cable terminal ring, and frame.

- Apply BLUE dielectric grease to battery terminal stud, negative battery cable ring terminal, and threads of battery terminal nut.

- Connect negative battery cable to battery stud.

- Install battery terminal nut. Using a torque wrench, tighten battery terminal nut to 12 to 15 lb-ft (16.3 to 20.3 N•m).

- Inspect and apply BLUE dielectric grease to bare spots of battery terminal nut, stud, and ring terminal.

- Secure battery ground cable with cable tie strap (Figure 1, Item 3), tighten cable tie strap. Remove excess material from cable tie strap.

- Does truck being serviced have additional wiring in battery box?

a. Yes – there is additional wiring, proceed to Step 44.

b. No – proceed to Step 48.

Population 2 – Service Instructions for Vehicles Built 11 November 2019 thru 03 March 2021

CAUTION! To prevent damage to property or vehicle components, the RED sealant paint must be thoroughly softened and fully removed from bolt and threads. Avoid drip onto unwanted surfaces. DO NOT apply to rubber, wire insulation and the like, only metallic surfaces.

- Shake Blue Bear Gel Softener container to homogenize contents. Slowly open container.

- Pour needed amount of softener into small metal container. Using a paint brush, apply liberally on to RED coated threads, nuts and studs (metal surfaces).

- Let softener sit for 10-15 minutes. Longer set time will yield better results.

- Using scraper, wire brush, and rag, remove as much coating as possible. Second application of softener may be required; use discretion prior to loosening nut and bolt.

- Using abrasive pad or cloth dipped in odorless mineral spirits, remove remaining finish or residue.

- Disconnect battery ground cable at frame. Save bolt and nut for reuse. Discard battery ground cable only.

- Clean negative battery cable connection point on frame.

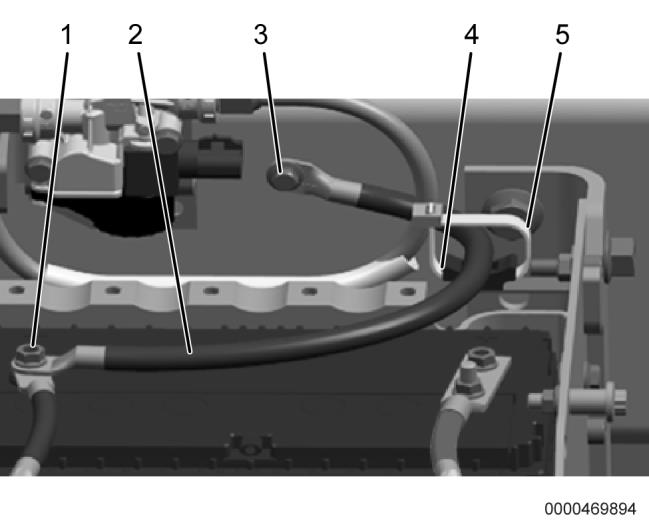

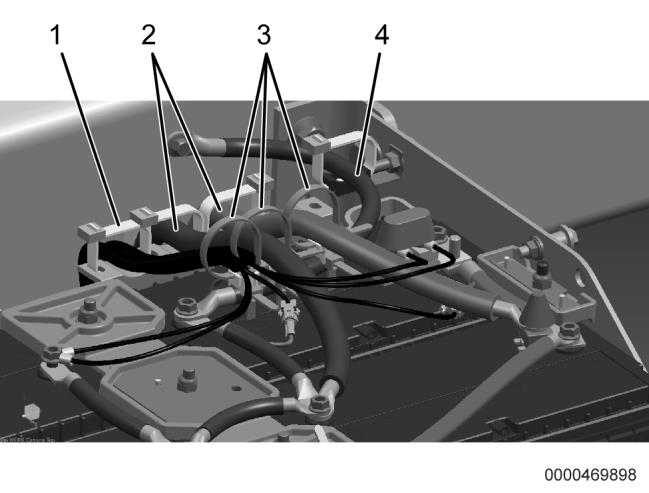

Figure 2. Routing for Truck for Population 2

-

- Battery stud nut

- Negative battery cable

- Battery cable frame bolt and nut

- Saddle clamp

- Extension clip

- Route new negative battery ground cable to frame (Figure 2, Item 2) and under all other harnesses that may be in battery box.

- Clean battery terminal with wire brush. Then clean with electrical contact cleaner and dry with shop air.

- Install battery cable frame bolt (Figure 1, Item 3); install new ground cable and nut previously removed in Step 32 (Figure 1, Item 23). Using torque wrench, tighten cable frame nut to 31 lb-ft (42 N•m).

- Apply RED sealant paint and thoroughly coat frame bolt, bolt threads, nut, battery ground cable terminal ring and frame.

- Apply BLUE dielectric grease to battery terminal stud, negative battery cable ring terminal and threads of battery terminal nut.

- Connect negative battery cable to battery stud.

- Install battery terminal nut. Using a torque wrench, tighten battery terminal nut to 12 to 15 lb-ft (16.3 to 20.3 N•m).

- Inspect and apply BLUE dielectric grease to bare spots of battery terminal nut, stud and ring terminal.

- Assemble saddle clamp (Figure 2, Item 4) to extension clip (Figure 2, Item 5) from kit.

- Remove existing bolt and nut from battery box and install extension clip and tighten fastener (Figure 2, Item 5).

- Secure negative battery cable to saddle clamp (Figure 2, Item 4), tighten cable tie strap. Remove excess material from cable tie strap.

- Check if vehicle is equipped with additional wiring in battery box in location of newly installed negative battery cable.

a. No – proceed to Step 50.

b. Yes – there is additional wiring and clipping required. Perform all additional steps for all additional options the truck you are working on is equipped with. Once all necessary additional steps have been completed, proceed to Step 50.

i. Inverter system wiring: 0008XDM, 0008XLD

-

-

- Refer to Step 45

-

ii. Lift gate wiring

-

-

- Refer to Step 46

-

iii. No-idle system

-

-

- Refer to Step 47

-

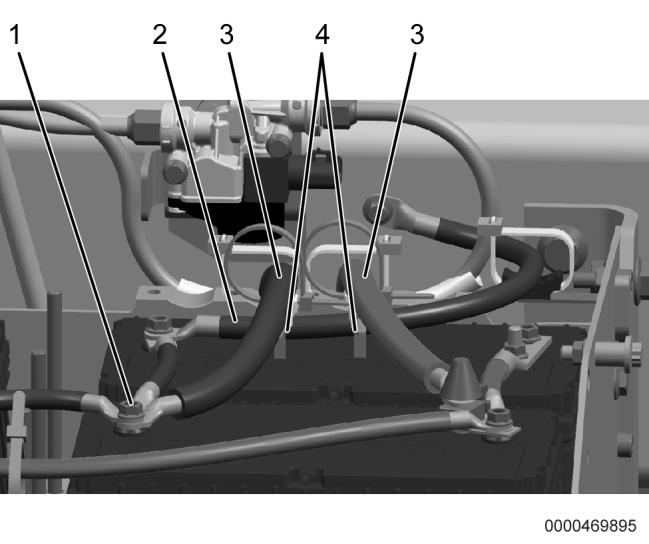

Figure 3. Routing for Truck with Inverter Systems

-

- Battery stud nut

- Negative battery cable

- Inverter power and ground cable (2)

- Swivel saddle

- Inverter Cable Wiring:

a. Install swivel saddle (Figure 3, Item 4) between negative battery cable and both inverter cables. Secure both swivel saddles in place with cable tie straps. Tighten cable tie straps and remove excess material from cable tie straps.

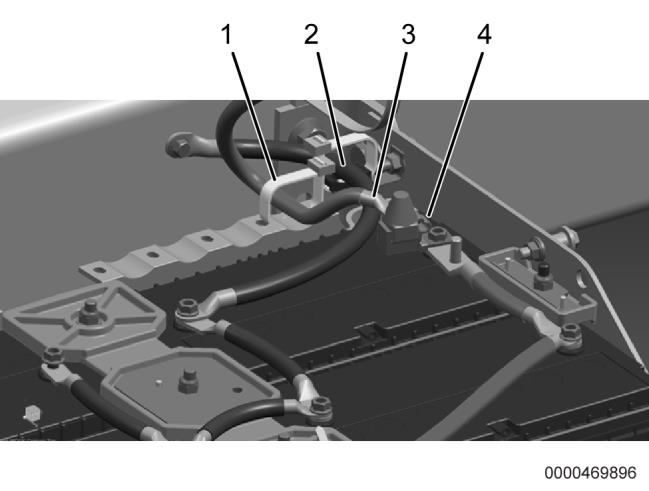

Figure 4. Routing for Truck with Lift Gate Wiring

-

- Cable tie strap

- Negative battery cable

- Lift gate wiring

- Cube fuse for lift gate wiring

NOTE: If Step 48 b and c are performed, remove, clean and reuse battery stud nut. Reapply BLUE dielectric grease.

- Lift Gate Wiring:

a. Inspect for clearance between newly installed negative battery cable and wiring for lift gate wiring (Figure 4, Items 2 and 3).

b. If little to no clearance, loosen cable on cube fuse and battery nut.

c. Rotate cube fuse to gain clearance, apply dielectric grease to battery stud and threads of nut. Install nut. Using torque wrench, tighten battery terminal nut to 12 to 15 lb-ft (16.3 to 20.3 N•m).

d. Install swivel saddle between negative battery cable and lift gate wiring (Figure 4, Items 2 and 3) (swivel clamp NOT shown). Secure in place with cable tie straps. Tighten cable tie straps and remove excess material from cable tie strap.

No-Idle HVAC Cabling

Figure 5. Routing for Truck with No-Idle HVAC

-

- No-idle HVAC cabling

- Battery stud nut

- Swivel saddle

- Negative battery cable

- Saddle clamp

- No-Idle HVAC Wiring

a. Install swivel saddle (Figure 5, Item 3) between negative battery cable and no-idle HVAC cabling and secure in place with cable tie straps. Tighten cable tie straps and remove excess material from cable tie straps.

Inverter Wiring and No-Idle HVAC Wiring

Figure 6. Cable Routing: When Equipped with Inverter Wiring and No-Idle HVAC

-

- No-idle HVAC wiring

- Inverter power and ground cable (2)

- Swivel saddle (3)

- Negative battery cable

NOTE: Figure 6 illustrates battery box when equipped with both inverter wiring and no-idle HVAC.

- Inspect all cables to verify there is clearance and no rub points. Adjust as required.

- Reinstall aerodynamic skirt if removed in Step 5.

- Remove wheel chocks.

END OF SERVICE PROCEDURE

LABOR INFORMATION

| Operation Number | Description | Time |

| A40-21501-1 | Replace Battery Cable using K2H2212035 | 0.4 hrs |

| A40-21501-2 | Replace Battery Cable using 8900291R91 | 0.5 hrs |

| A40-21501-3 | Soften / Remove Red Sealant Paint; If Necessary | 0.2 hrs |

| A40-21501-4 | Remove and Install Skirt; If Necessary | 0.2 hrs |

CAMPAIGN IDENTIFICATION LABEL

Each vehicle corrected in accordance with this campaign must be marked with a CTS-1075 Campaign Identification Label.

Complete the label and attach on a clean surface next to the vehicle identification number (VIN) plate.

ADMINISTRATIVE / DEALER RESPONSIBILITIES

WARRANTY CLAIMS

Warranty claim expense is to be charged to Warranty. Claims are to be submitted in the normal manner, making reference to Safety Recall 21501. Section 7 of the Warranty Policy and Procedures manual contains further information related to the submission and processing of AFC/Recall claims. As with all claim submissions, items acquired locally must be submitted in the “Other Charges” tab. The cost of any bulk items (such as a bag of cable tie straps, roll of wire, a barrel of oil, or a tube of silicone) should be prorated for the cost of the individual pieces / amount used during each repair.

UNITED STATES AND POSSESSIONS

The National Traffic and Motor Vehicle Safety Act, as amended, provides that each vehicle that is subject to a vehicle recall campaign must be adequately repaired within a reasonable time after the owner has tendered it for repair. A failure to adequately repair within 60 days after a tender of a vehicle is prima facie evidence of failure to repair within a reasonable time. If the condition is not adequately repaired within 60 days, the owner may be entitled to replacement with an identical or reasonable equivalent vehicle at no charge, or to a refund of the purchase price less a reasonable allowance for depreciation.

Dealers must correct all vehicles subject to this campaign at no charge to the owner, regardless of mileage, age of vehicle, or ownership, from this time forward.

Dealers should proceed immediately to make necessary correction to units in inventory. All inventory vehicles subject to this recall campaign must be corrected prior to sale, transfer or delivery. If vehicles have been sold or transferred and you are in receipt of Customer Notification Letters and Authorization for Recall Service cards for those vehicles, the transfer location or customer must be notified immediately from your dealer location.

Dealers must make every effort to promptly schedule an appointment with each owner to repair his or her vehicle as soon as possible. However, consistent with the customer notification, dealers are expected to complete the repairs on the mutually agreed upon service date.

Dealers involved in the recall process will be furnished a listing of owner names and addresses to enable them to follow up with owners and have the vehicles corrected. Use of this listing must be limited to this campaign because the list may contain information obtained from state motor vehicle registration records, and the use of such motor vehicle registration data for purposes other than this campaign is a violation of law in several states.

CANADA

Dealers must correct all vehicles subject to this campaign at no charge to the owner, regardless of mileage, age of vehicle, or ownership, from this time forward.

Dealers should proceed immediately to make necessary correction to units in inventory. All inventory vehicles subject to this recall campaign must be corrected prior to sale, transfer or delivery. If vehicles have been sold or transferred and you are in receipt of Customer Notification Letters and Authorization for Recall Service cards for those vehicles, the transfer location or customer must be notified immediately from your dealer location.

Dealers must make every effort to promptly schedule an appointment with each owner to repair his or her vehicle as soon as possible. However, consistent with the customer notification, dealers are expected to complete the repairs on the mutually agreed upon service date.

Dealers involved in the recall process will be furnished a listing of owner names and addresses to enable them to follow up with owners and have the vehicles corrected. Use of this listing must be limited to this campaign because the list may contain information obtained from state motor vehicle registration records, and the use of such motor vehicle registration data for purposes other than this campaign is a violation of law in several states.

EXPORT

Export Distributors should proceed immediately to make necessary correction to units in inventory. All inventory vehicles subject to this recall campaign must be corrected prior to sale, transfer or delivery. If vehicles have been sold or transferred and you are in receipt of Customer Notification Letters and Authorization for Recall Service cards for those vehicles, the transfer location or customer must be notified immediately from your distributor location.

Export Distributors are to submit warranty claims in the usual manner making reference to this recall number.

Export Distributors are expected to provide full cooperation and follow-up with respect to this important subject matter. If you have any questions or need further assistance, please contact the Regional Service Manager at your regional office.

NAVISTAR, INC.

IMPORTANT SAFETY RECALL 21501

NHTSA RECALL NO. 21V-079

This notice applies to your vehicle identified on the enclosed card.

APRIL 2021

Dear INTERNATIONAL® Customer,

This notice applies to your vehicle identified on the enclosed card. This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act.

Navistar has decided that a defect which relates to motor vehicle safety exists in certain 2017 thru 2021 LT® series trucks built 05/18/2016 thru 03/03/2021 and 2018 thru 2021 Lonestar® series trucks built 07/21/2017 thru 12/16/2020 with Cummins X15 or ISX engines and equipped with Feature Code 08XHK or 08XHL (Battery Box, mounted on left side under cab).

REASON FOR THIS RECALL

The battery ground cable may break at the frame connection resulting in loss of electrical power and unintended engine shut down without warning.

RISK TO MOTOR VEHICLE SAFETY

Unintended engine shut down without warning may result in a vehicle being stalled on the side of the roadway which could increase the risk of a vehicle crash.

DEFECT REMEDY

The repair will involve replacing the battery ground cable with a new cable design. Authorized repair locations have parts and instructions to repair your vehicle. The repair will be performed free of charge and take approximately 45 minutes to complete.

ACTIONS YOU SHOULD TAKE

If you own this vehicle, please contact any INTERNATIONAL® dealer or a Love’s Truck Tire Care or Speedco* location to have your vehicle repaired at no cost to you. You can find your nearest service location by calling 1-800-448-7825 or by using the service locator at https://www.internationaltrucks.com or

https://www.loves.com .

*Love’s and Speedco locations in Texas cannot perform warranty services.

If you have already paid for repairs prior to this notice that corrected the defect, you may be eligible for reimbursement of certain repair expenses if they occurred 12/17/2020 thru 04/26/2021. Present your original repair paperwork and proof of payment to any INTERNATIONAL® dealer and your eligibility will be reviewed. You may also submit a claim using the enclosed Request for Reimbursement card.

If you are the lessor of this vehicle, please forward a copy of this notice to the lessee within ten days to compty with federal regulations.

If you do not own this vehicle, please fill out and return mail the enclosed card so that you will not be contacted again about this recall.

IF YOU NEED FURTHER ASSISTANCE

If you believe that Navistar has failed to remedy the defect without charge or within a reasonable time, please follow the procedure described in the Owner Assistance Guide section in your Owner’s Manual or call toll free 1-800-448-7825.

You may also submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave, SE, Washington, DC 20590; or call the toll free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153); or go to https://www.safercar.gov.

Navistar requests your prompt attention and patience regarding the correction of this defect and apologizes for any inconvenience this may cause you.

Navistar, Inc.

Navistar Recall 21501 Chronology of Events

- 05/18/2020 Navistar Field Service receives first communication from a fleet customer that a negative battery cable detached from the frame.

- 06/23/2020 Navistar Field Service receives a second communication from a fleet customer that a battery ground cable ring terminal broke causing the ground cable to separate from the frame, which caused the engine to shut down. This was the first identified report that the vehicle shut down after a ring terminal failure.

- 07/06/2020 Navistar Compliance reviews customer concerns related to negative battery cable failures.

- 07/14/2020 Navistar Compliance and Reliability meet to review warranty claims for negative battery cable replacement.

- 07/23/2020 Navistar Compliance, Reliability, and Engineering meet and initiate Finite Element Analysis (FEA) testing to determine likelihood of a repetitive failure mode.

- 08/11/2020 Navistar Compliance and Engineering meet to review results of the FEA. The FEA analysis showed elevated stresses at the bend in the ring terminal, however no conclusions could be made relating to a life prediction.

- 08/14/2020 Navistar Compliance, Reliability, and Engineering meet and initiate Weibull analysis to predict mileage for the ring terminal failures. Due to the low number of claims in the warranty period, and no other reports of vehicle shut down, the data was inconclusive.

- 08/27/2020 Navistar Compliance Committee meet to discuss the failure mode and warranty history of the negative battery cable. Navistar Engineering receives confirmation to proceed with physical tests to validate the FEA analysis.

- 09/10/2020 Navistar receives previous Prostar and early LT battery cables to perform dimension and material evaluation compared to previous failed cables in the field. Material evaluation concluded all failed parts were within material and dimensional specification.

- 09/11/2020 Navistar engineers meet to discuss common characteristics within the warranty failures. Navistar also requested information from the supplier to verify if any tooling change occurred for the terminal and retrieved additional failed battery cables to analyze.

- 09/16/2020 The Battery Cable supplier confirmed there was no tooling change and was in the process reviewing sub supplier material.

- 09/23/2020 The supplier reported that no material changes or tooling changes were made by their sub supplier.

- 10/01/2020 Navistar Compliance Committee meets to discuss Weibull, the field findings of possible misrouted battery cables. No new warranty claims or field reports were found since the 8/14/20 meeting. However, in analyzing the claim data, there were five claims reporting vehicle shutdown in 2019, and four in 2020. The Committee agreed to begin vibration testing in an attempt to recreate the failure mode.

- 10/03/2020 Bench vibration testing could not reproduce the ring terminal failure mode.

- 10/07/2020 Navistar requests a customer vehicle that had experienced negative battery cable breakage to perform additional testing.

- 11/03/2020 through 11/16/2020 Navistar performs strain test on ring terminal performing certain vehicle maneuvers on vehicle received from customer.

- 11/18/2020 Navistar Compliance Committee meet to discuss the results of the strain test and the potential root cause resulting in the stress on the ring terminal. Certain vehicle maneuvers did cause stress rates above what is believed to be normal for a copper terminal. The Committee requested actions to investigate and evaluate chassis racking as the root cause, review current production failures, and perform additional testing on current production vehicles.

- 12/03/2020 through 01/23/2021 Navistar initiates plans and testing for additional vehicle battery cable configurations designs of current production for similar failure modes.

- 01/14/2021 Navistar Compliance, Data Analytics and Engineering meet to identify potential suspect population based on certain vehicle characteristics.

- 01/29/2021 Navistar Compliance Committee meets to review test results on current configuration design and strain test results confirm current configuration design experienced high stress on the ring terminal as well.

- 02/03/2021 Navistar finalizes the suspect population based on certain vehicle configuration and characteristics.

- 02/11/2021 Navistar discusses final vehicle testing and suspect vehicle configurations and declares a Safety Recall.

9 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| INTERNATIONAL | LONESTAR | 2018-2021 |

| INTERNATIONAL | LT | 2017-2021 |

11 Associated Documents

Remedy Instructions and TSB

RCRIT-21V079-5719.pdf 425.387KB

Loading...

Loading...

Recall Quarterly Report #1, 2021-2

RCLQRT-21V079-9535.PDF 211.137KB

Loading...

Loading...

Recall Acknowledgement

RCAK-21V079-9687.pdf 645.814KB

Loading...

Loading...

Recall 573 Report- Amendment 1

RCLRPT-21V079-2234.PDF 213.848KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-21V079-4919.PDF 213.837KB

Loading...

Loading...

Miscellaneous Document- Chronology

RMISC-21V079-5593.pdf 45.383KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-21V079-8786.pdf 366.254KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-21V079-8330.pdf 483.932KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-21V079-1224.pdf 44.809KB

Loading...

Loading...

Recall Quarterly Report #2, 2021-3

RCLQRT-21V079-7683.PDF 211.244KB

Loading...

Loading...

Recall Quarterly Report #3, 2021-4

RCLQRT-21V079-3512.PDF 211.331KB

Loading...

Loading...

Latest Recalls Documents

https://www-odi.nhtsa.dot.gov/acms/cs/documentList.xhtml?docId=21V079&docType=RCL

- 4 AWG wire, fits 3/8" stud, SAE 4 GAUGE COPPER

- Zinc plated 95% copper lugs for superior corrosion and oxidation resistance

- Better stamping process to improve the current and reduce the resistance.

- Boat cable wire stays ultra flexible even in the most extreme conditions

- Heat-resistant up to 105C

- 2 gauge battery/welding cable with 3/8 " lugs

- Can be used on variety of applications, such as automotive, solar, marine, boat, rv, car, motorcycle, etc

- The battery cable is made of high quality PVC insulation sheath, each cable end is sealed with heat shrink tubing for heat insulation

- Copper Cable lugs are made of solid copper with a tin plating cover for corrosion protection

- Please carefully check all the product information to make sure this is the right one you want before placing an order

- ENERGIZER 16 FEET JUMPER CABLES - 6 Gauge, 16 FT booster battery jumper cables for jump starting a dead or weak battery. Ideal for trucks, SUVs, full-size cars, mid-size cars and small/compact cars

- THICK VINYL COATING - Includes a strong spring and a comfortable handle for secure placement and easy positioning. Thick vinyl coating for protection against rust and corrosion.

- CARRYING CASE INCLUDED - Our Energizer jumper cables come with a high-grade travel bag for easy transport and compact storage.

- TANGLE FREE CCA BOOSTER CABLES - 16 Foot length makes it easy to reach from one car battery to another. Copper clad aluminum cables remains flexible even at -40°C.

- THE BRAND NAME YOU CAN TRUST - 2 Years Warranty! We are here to power your car battery and truck with our booster jumper cables. We keep you going and going!

- Fit for Automotive Solar Marine Boat RV Car Motorcycle

- 4 gauge battery/welding cable with 3/8 " lugs; Battery Cable Length: 4 Feet

- Package will come with each one of the red and black cable, each cable end is sealed with heat shrink tubing for heat insulation

- Copper Cable lugs are made of solid copper with a tin plating cover for corrosion protection

- Please feel free to contact us if you have any questions about our products, your satisfaction would be our greatest motivation

- 【High Quality】A ABIGAIL battery cables are made of pure copper and tinned copper lugs with superior corrosion and oxidation resistance, which improves the oxidation resistance of copper and maintains its conductivity better.

- 【Safe & Durable】Premium flexible PVC insulated jacke of battery cables which resists abrasion, waterproof and moisture proof, flame retardant and heat insulation, cable ends are sealed with heat shrink tubing for heat insulation.

- 【Wide Application】Our positive and negative cables are widely used for car automotive, solar, marine, RV, motorcycle, golf cart, lawn/garden equipment or power inverter batteries, also used for electrical equipment.

- 【Package Includes】With 2 AWG 12 Inch wire positive (Red) and negative (Black) copper battery cables, 3/8” ring terminal at each end.

- 【Service】100% satisfaction guarantee, If you have any issues with the part, simply contact customer service for troubleshooting help, parts, replacement, or refund. Our aim is to make you satisfy the parts and the service we provide for you.

- Heavy Duty: one set of 5 gauge wire positive (red) and negative (black) copper battery cables, 20 inch for every cable.

- Easy to Use: each cable have 2 pcs 3/8" (M10) round center hole terminals (already crimped) on both ends, fit for 3/8" (M10) stud.

- High Quality: copper cables for maximum power transfer, nickel plated copper lugs for superior corrosion and oxidation resistance.

- Safe & Durable: premium PVC insulated jacket for the cables, cable ends are sealed with heat shrink tubing for heat insulation.

- Compatible: used for car, vehicle, RV, solar application, boat and more, also used for electrical equipment.

- Sold as a set: 2 gauge battery cable, includes 1x positive(red) and 1x negative(black) cable. Length: 2ft, Gauge: 2AWG, fits 3/8" stud.

- Durable material: The copper 2 gauge battery cable lugs are tinned coated, well crimped, and utilize a closed end design for corrosion protection.Heat-resistant up to 105C.

- Easy to connect: These flexible 2 gauge battery cable are made with thinly stranded pure copper, making them easy to handle an install ,It can also be used normally in extreme environments.

- Use for: Marine battery cables are to withstand harsh environments. 2 gauge battery cable is ideal for various equipments, inverter batteries, cars, solar energy, RV, boat, etc.

- Warranty: 1 year warranty, 30 days worry-free return, if you have any questions, our customer service will be online 24 hours a day. You can buy our 2 gauge battery cable with confidence.

- 100% Pure Copper-OFC: These 4 AWG wires made from high-quality imported copper materials and using unique and exquisite craftsmanship.

- Excellent Conductivity: It has the highest conductivity and thermal conductivity, very low resistance, and can effectively reduce wire losses and improve power transmission efficiency.

- Good Corrosion Resistance: The oxidation resistance and corrosion resistance of pure copper wire, even in harsh environments such as high temperature and humidity, are not easy to rust and corrode, and can still work stably and reliably.

- High Plasticity: It can be made into various shapes and sizes of wires according to process requirements, and has high flexibility and torsion. When building various circuits, it can meet your needs and adjust its shape and length.

- Wide Compatibility: Providing top-notch solutions for your various wiring needs, solar systems, RVs/trailers, boats, Auto and more. If you need other wire gauges or larger quantities, please contact us.

- The battery cable replacement is designed to fit for automotive, solar, marine, boat, rv, car, motorcycle, etc

- Package comes with 2 pcs 6 AWG battery cables, each cable has two 5/16 inch tinned copper ring terminals

- Wires have 5/16 inch hole allowing it to fit over battery disconnects/switches. The tinned copper wires prevent corrosion and allow for more easily soldering

- Temperature Range: -45°C to +105°C; Length: 3FT

- Please carefully check all the product information to make sure this is the right one you want before purchasing

- Premium Material: Battery Cable is made of Copper, which has good electrical conductivity.

- Wide Applications: Battery Cable can be used for car, vehicle, RV, Truck, solar application, boat, etc.

- Durable & Safe: The exterior of the Battery Cable is made of premium PVC insulated jacket, which has good thermal insulation.

- Easy to use: The battery cables with two ring terminals that can be used to connect the battery disconnects/switch. The copper wires prevent corrosion and allow for more easily soldering.

- What you get: 2PCS Copper Battery Cables.

Last update on 2024-06-11 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.