| “This site contains affiliate links for which OEMDTC may be compensated” |

June 3, 2020 NHTSA CAMPAIGN NUMBER: 20V322000

Front Seat Wiring Harnesses Routed Incorrectly

If the wiring harness is damaged, the side air bag within the seat may deploy inadvertently or not deploy as designed in the event of a crash, increasing the risk of injury to vehicle occupants.

NHTSA Campaign Number: 20V322

Manufacturer Daimler Vans USA, LLC

Components ELECTRICAL SYSTEM, AIR BAGS, SEATS

Potential Number of Units Affected 11,013

Summary

Daimler Vans USA, LLC (DVUSA) is recalling certain 2019 Mercedes-Benz and Freightliner Sprinter vans (platform 970 (VS30)), equipped with swivel seats. The wiring harnesses for the front seats may have been routed incorrectly and could become jammed and damaged in the swivel seat frames.

Remedy

DVUSA will notify owners, and an authorized Mercedes-Benz or Freightliner Sprinter dealer will inspect the wire harness routing for both front seats and will repair the wiring and add clips or cable ties as needed, free of charge. Owners may contact DVUSA customer service at 1-877-762-8267. DVUSA’s number for this recall is VS3DREHSIK.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check for Daimler Vans Recalls

| TO: Mercedes-Benz and Freightliner Dealer Principals, General Managers, Sales Managers, Service Managers, Parts Managers | FROM: Anthony Washington, Department Manager, Regulations and Certifications |

| RE: Initial Recall Campaign Notification Model 907 (Sprinter) Model Years 2019 – 2020 Inspect Front Swivel Seat Wiring |

DATE: June 16, 2020 |

IMPORTANT RECALL CAMPAIGN INFORMATION

Please see the attached documents related to the campaign listed above

| Campaign | Campaign Desc. : | Inspect Front Swivel Seat Wiring | |

| TBD | PDGDREHSIK | ||

| This is to notify you of the upcoming Recall Campaign concerning the installation of the seat wiring harness on approximately 11,013 MY19-20 Mercedes-Benz and Freightliner Sprinter vans. The recall campaign will be visible on the www.safercar.gov website and may generate questions from customers. All affected VINs will be flagged as “Pending” in VMI. | |||

| Background | |||

| Issue | Mercedes-Benz AG (“MBAG”), the manufacturer of Mercedes-Benz and Freightliner vans, has determined that on certain Sprinter vehicles from platform 907 (VS30) that are equipped with front swivel-seats, the electric cables in the seat wiring harness could become jammed and damaged in the swivel-seat frame. If electric cables in the wiring harness become jammed and damaged in the swivelseat frame, the operation of the side airbag within the seat could be adversely affected which could cause the side airbag to deploy inadvertently or not deploy as designed in the event of a crash, increasing the risk of injury to vehicle occupants. | ||

| What We’re Doing | An authorized Mercedes-Benz or Freightliner Sprinter dealer will inspect the installation of the seat wiring harness (left/right) of the front seats and will add clips or cable ties, as needed, to ensure that the course routing is according to specification. | ||

| Parts | Parts are still being verified. An additional notification will be sent when parts are available for repair. | ||

| Vehicles Affected | |||

| Vehicle Model Year(s) | Model Year 2019 – 2020 | ||

| Vehicle Model | Sprinter, VS30 / Platform 907 | ||

| Vehicle Populations | |||

| Total Recall | 11,013 | ||

| Dealer Inventory | 600 | ||

| Given this notice, it is a violation of Federal Law for a dealer to sell or lease any new MY19-20 Sprinter vehicles in dealer inventory covered by this notification until the vehicle has been repaired.

Loaner and demonstrator vehicles may continue to be driven, but must not be retailed until repaired. Additionally, given this notice, it is a violation of Federal Law for rental companies to rent new MY19-20 Sprinter vehicles covered by this notification until the vehicle has been repaired. |

|||

| Next Steps/Notes | |||

| Customer Notification Timeline | An owner notification letter will be mailed in mid-July 2020. | ||

| AOMS/SOMS | AOMs – This recall may generate questions from your dealers. Please forward this notice to your dealers ASAP. | ||

| Rental Fleet Partners | This recall may affect vehicles in your fleet. Please contact your respective DVUSA fleet representative for further information and next steps. For repairs, please contact your preferred DVUSA dealer. | ||

| While we regret any inconvenience this may cause, we are determined to maintain a high level of vehicle quality and customer satisfaction. | |||

IMPORTANT SAFETY RECALL INTERIM NOTICE

This notice applies to your vehicle,

Front Swivel Seat Wiring VIN: WD3PE7CC0A

NHTSA Recall #20V322

July, 2020

20V322

WD3PE7CC0

- A safety defect exists in your vehicle.

- Remedy parts are not yet available for your vehicle.

- We will contact you again once parts are available.

Dear Valued Freightliner Sprinter Owner:

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act.

Mercedes-Benz AG (“MBAG”), the manufacturer of Sprinter vans, has decided that a defect which relates to motor vehicle safety exists in certain Model Year 2019 – 2020 Freightliner Sprinter vehicles. Our records indicate that your vehicle is included in the affected population of vehicles.

MBAG has determined that on certain Freightliner Sprinter vehicles, that are equipped with front swivel-seats, the electric cables in the seat wiring harness could become jammed and damaged in the swivel-seat frame. If electric cables in the wiring harness become jammed and damaged in the swivel-seat frame, the operation of the side airbag within the seat could be adversely affected which could cause the side airbag to deploy inadvertently or not deploy as designed in the event of a crash, increasing the risk of injury to vehicle occupants.

We want to assure you that MBAG is taking all necessary measures to remedy this situation for you. We are also working closely with the National Highway Traffic Safety Administration (“NHTSA”) and suppliers to provide a remedy as soon as possible. Unfortunately, replacement parts are not yet available for your vehicle, and we will contact you again once parts become available.

As soon as a suitable replacement part is available for your vehicle, we will send another letter notifying you to bring your vehicle to your local authorized Freightliner Sprinter dealer to repair your vehicle free of charge. In the meantime, please visit

www.freightlinersprinterusa.com/freightliner/owners-resources/recall and enter your 17 digit VIN in the VIN Look-up tool, then enter your most recent contact information.

We also encourage you to sign up for recall alerts at www.nhtsa.gov/alerts.

In the event that you are no longer the vehicle owner, or have had a change of address, please complete the reverse side and return the updated information in the enclosed envelope. If this is a leased vehicle and the lessor and registered owner receive this notice, please forward this information by first class mail to the lessee within 10 business days to comply with Federal Regulations.

We apologize for any inconvenience this situation may cause you.

Sincerely,

Daimler Vans USA, LLC

One Mercedes-Benz Drive

Sandy Springs, GA 30328

Phone (770) 705-0600

IMPORTANT VIN:

If for any reason YOU NO LONGER OWN THIS VEHICLE OR have a CHANGE OF ADDRESS, please COMPLETE THE SECTION BELOW, place in the ENCLOSED ENVELOPE, and DROP IN ANY MAIL BOX. If possible, provide the name and address of the present owner so that we may contact them.

| TO: Mercedes-Benz and Freightliner Dealer Principals, General Managers, Sales Managers, Service Managers, Parts Managers | FROM: Anthony Washington, Department Manager, Regulations and Certifications |

| Re: Recall Campaign Notification Model 907 (Sprinter) Model Years 2019 – 2020 Inspect Front Swivel Seat Wiring |

DATE: August 5, 2020 |

IMPORTANT RECALL CAMPAIGN INFORMATION

Please see the attached documents related to the campaign listed above

| Campaign | Campaign Desc. : | Inspect Front Swivel Seat Wiring | |

| 2020070011 | VS3DREHSIK | ||

| This is to notify you of the upcoming Recall Campaign concerning the installation of the seat wiring harness on approximately 11,013 MY19-20 Mercedes-Benz and Freightliner Sprinter vans. The recall campaign will be visible on the www.safercar.gov website and may generate questions from customers. All affected VINs will be flagged as “OPEN” in VMI. | |||

| Background | |||

| Issue | Mercedes-Benz AG (“MBAG”), the manufacturer of Mercedes-Benz and Freightliner vans, has determined that on certain Sprinter vehicles from platform 907 (VS30) that are equipped with front swivel-seats, the electric cables in the seat wiring harness could become jammed and damaged in the swivel-seat frame. If electric cables in the wiring harness become jammed and damaged in the swivelseat frame, the operation of the side airbag within the seat could be adversely affected which could cause the side airbag to deploy inadvertently or not deploy as designed in the event of a crash, increasing the risk of injury to vehicle occupants. | ||

| What We’re Doing | MBUSA/DVUSA is conducting a voluntary recall. An authorized Mercedes-Benz or Freightliner Sprinter dealer will inspect the installation of the seat wiring harness (left/right) of the front seats and will add clips or cable ties as needed to ensure that the harness routing is according to specification. | ||

| Parts | Parts are available. | ||

| Vehicles Affected | |||

| Vehicle Model Year(s) | Model Year 2019 – 2020 | ||

| Vehicle Model | Sprinter, VS30 / Platform 907 | ||

| Vehicle Populations | |||

| Total Recall | 11,013 | ||

| Dealer Inventory | 428 | ||

| Given this notice, it is a violation of Federal Law for a dealer to sell or lease any new MY19-20 Sprinter vehicles in dealer inventory covered by this notification until the vehicle has been repaired.

Loaner and demonstrator vehicles may continue to be driven, but must not be retailed until repaired. Additionally, given this notice, it is a violation of Federal Law for rental companies to rent new MY19-20 Sprinter vehicles covered by this notification until the vehicle has been repaired. |

|||

| Next Steps/Notes | |||

| Customer Notification Timeline | An owner notification letter will be mailed in mid-August 2020. | ||

| AOMS/SOMS | AOMs – This recall may generate questions from your dealers. Please forward this notice to your dealers ASAP. | ||

| Rental Fleet Partners | This recall may affect vehicles in your fleet. Please contact your respective MBUSA/DVUSA fleet representative for further information and next steps. For repairs, please contact your preferred MBUSA/DVUSA dealer. | ||

| While we regret any inconvenience this may cause, we are determined to maintain a high level of vehicle quality and customer satisfaction. | |||

Campaign No. 2020070011, August 2020

| TO: | ALL MERCEDES-BENZ CENTERS |

| SUBJECT: | Model 907 (Sprinter), Model Year 2019 – 2020 Front Swivel Seat Wiring |

Mercedes-Benz AG (“MBAG”), the manufacturer of Mercedes-Benz and Freightliner vans, has determined that on certain Sprinter vehicles from platform 907 (VS30) that are equipped with front swivel-seats, the electric cables in the seat wiring harness could become jammed and damaged in the swivel-seat frame. If electric cables in the wiring harness could become jammed and damaged in the swivel-seat frame. In that case, the operation of the side airbag within the driver and/or front passenger seats could be adversely affected which could cause the side airbag to deploy inadvertently or not deploy as designed in the event of a crash, increasing the risk of injury to vehicle occupants. An authorized Mercedes-Benz or Freightliner Sprinter dealer will inspect the installation of the seat wiring harness (left/right) of the front seats and will repair as necessary.

Prior to performing this Recall Campaign:

- Please check VMI to determine if the vehicle is involved in the Campaign and if it has been previouslyrepaired.

- Please review the entire Recall Campaign bulletin and follow the repair procedure exactly as

Please note that Recall Campaigns do not expire and may also be performed on a vehicle with a vehicle status indicator.

Approximately 11 013 vehicles are involved.

Order No. V-RC-2020070011

Operation no. of the operation texts or standard texts and flat rates

Operation no. of the operation texts or standard texts and flat rates

| Op. no. | Operation text | Time | Damage Code |

| 02 1861 | Operations: Modify line installation for front seat | 0.7 h | 91 902 58 |

| 02 1862 | Operations: Modify line installation for 2 front | 1.1 h | 91 902 58 |

| 02 1863 | Operations: Extra work for: Perform modification of front seat line installation on veh.

with code SH1/SH2 and code E30 |

0.1 h | 91 902 58 |

| 02 1864 | Operations: Extra work for: Perform modification of front seat line installation on veh.

with code SH1/SH2 and without code E30 |

0.2 h | 91 902 58 |

| 02 1865 | Operations: Extra work for: Perform modification of front seat line installation on veh.

with code SH1/SH2 and code E2I |

0.1 h | 91 902 58 |

| 02 1866 | Operations: Extra work for: Perform modification of front seat line installation on veh.

with code SH1/SH2 and code E2M |

0.1 h | 91 902 58 |

| 02 1867 | Operations: Extra work for: Perform modification of front seat line installation on veh.

with code SH1/SH2 and code G42/G43 |

0.1 h | 91 902 58 |

| Warning | Risk of injury during testing and repair operations related to pyrotechnical components | Do not expose pyrotechnical component parts to temperatures above 100 ℃ or 212 °F. Disconnect current supply when working on such component parts. | AS91.00-Z-0008-01A |

| Topical note | Information on preventing damage to electronic components due to electrostatic discharge | AH54.00-P-0001-01A | |

| Topical note | Notes on carrying out repair work in the vehicle interior | AH68.00-N-0001-01S | |

| Information, assessment and legal requirements when working with, handling and storing pyrotechnical

components |

AH91.00-Z-0000-10A |

| Check | |||

| 1 | Check whether vehicle is affected by measure | Affected vehicles: Perform modification of line installation of rotating seats (code: VS3DREHSIK, acc. no.: 91 902 58)

Model 907.### #N as of 021191 up to 080037 with code SR8 (Swivel base for driver’ seat) Model 907.### #N as of 021191 up to 080037 with code SR9 (Swivel base for co-driver’ seat) Model 907.### #P as of 001743 up to 196899 with code SR8 (Swivel base for driver’ seat) Model 907.### #P as of 001743 up to 196899 with code SR9 (Swivel base for co-driver’ seat) Model 907.### #T as of 002698 up to 023183 with code SR8 (Swivel base for driver’ seat) Affected vehicles: Perform modification of line installation of rotating seats (code: VS3DREHSIK, acc. no.: 91 902 58) Model 910.### #N as of 027206 up to 800288 with code SR8 (Swivel base for driver’ seat) Model 910.### #N as of 027206 up to 800288 with code SR9 (Swivel base for co-driver’ seat) Model 910.### #P as of 048306 up to 195796 with code SR8 (Swivel base for driver’ seat) Model 910.### #P as of 048306 up to 195796 with code SR9 (Swivel base for co-driver’ seat) For authorized Mercedes‑Benz service partners, only the entry in the “Extended VEGA Application” (EVA) system, in the “Current” tab, is decisive. There is no need to also check the affected vehicles in the workshop information system (WIS) or vehicle list. |

SM91.10-D-0032-01AAA |

| SM91.10-D-0032-01AAB |

| Remove | |||

| 2 | Remove respective rotating seat. | ||

| Remove respective rotating seat from rotating seat console. Rotating seat console remains installed.

If rotating seats are installed on the driver and passenger side, then both rotating seats must be removed. |

AR91.10-D-1000TS | ||

| 3 | Perform modification of line installation and fastening of respective rotating seat. | Model 907, 910

with code SR8 (Swivel base for driver’ seat) except code SR9 (Swivel base for co-driver’ seat) |

Page 4 |

| Model 907, 910

with code SR9 (Swivel base for codriver’ seat) except code SR8 (Swivel base for driver’ seat) If rotating seats are installed on the driver and passenger side, then the line installation of both rotating seats must be modified. |

Page 7 | ||

| Install | |||

| 4 | Install respective rotating seat. | AR91.10-D-1000TS |

Parts ordering note

| Part no. | Designation | Quantity |

| A 002 997 24 90 | Detent strap | AS NEEDED |

| A 005 997 62 90 | Mounting clip | AS NEEDED |

| SM91.10-D-0032-02SGA | Modify line installation and mount of rotating seat (code: VS3DREHSIK, acc. no.: 91 902 58) | |

| Topical note | Notes on carrying out repair work in the vehicle interior | AH68.00-N-0001-01S |

Model 907, 910

with code SR8 (Swivel base for driver’ seat) except code SR9 (Swivel base for co-driver’ seat)

Vehicles with code SR8 (Driver’s seat rotating frame)

Perform steps 1 to 3 on vehicles that are only equipped with code SR8 (Driver’s seat rotating frame).

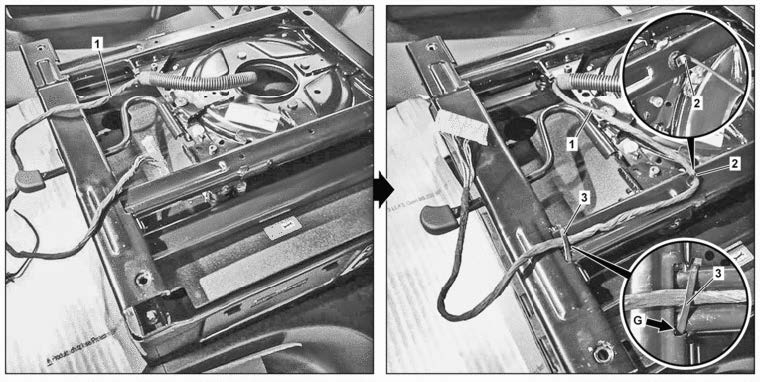

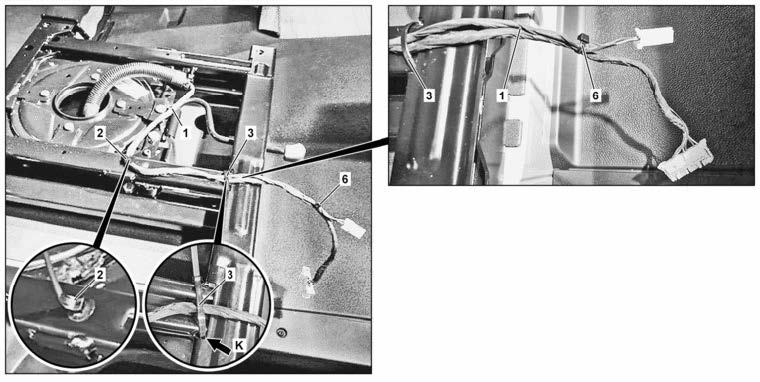

Shown with code SR8 (Driver’s seat swivel seat)

1 Electrical wiring harness

2 Mounting clip

3 Detent strap

1

Check whether electrical wiring harness (1) is fastened to central passage in rotating frame with retaining clip.

If not fastened,

↓

secure electrical wiring harness (1) to central passage using retaining clip.

2

Fasten electrical wiring harness (1) to rotating frame using retaining clip (2) as shown.

To do so, clip retaining clip (2) onto rotating frame as shown.

Pull electrical wiring harness (1) taut and fasten to retaining clip (2).

3

Fasten electrical wiring harness (1) to rotating frame using detent strap (3) as shown.

To do so, guide detent strap (3) through sheet metal opening (arrow G) and fasten.

Vehicles with code SR8 (Driver’s seat rotating frame) and code H16 (Seat heating for driver)

Steps 4 to 7 are to be performed on vehicles equipped with code SR8 (Driver’s seat rotating frame) and code H16 (Seat heating for driver).

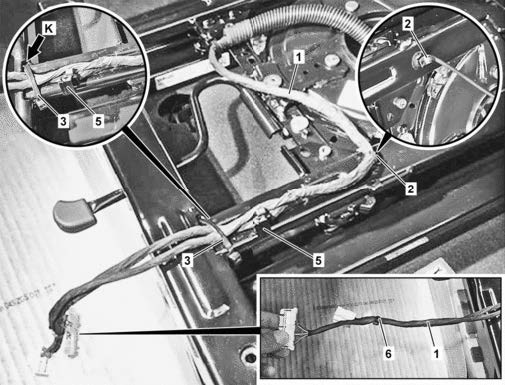

Shown with code SR8 (Driver’s seat rotating frame) and code H16 (Seat heating for driver)

1 Electrical wiring harness

2 Mounting clip

3 Detent strap

4 Mounting clip

5 Detent strap

4

Check whether electrical wiring harness (1) is fastened to central passage in rotating frame with retaining clip. If not fastened,

↓

secure electrical wiring harness (1) to central passage using retaining clip.

5

Fasten electrical wiring harness (1) to rotating frame using retaining clip (2) as shown.

To do so, clip retaining clip (2) onto rotating frame as shown.

Keep electrical wiring harness (1) taut and fasten to retaining clip (2).

6

Fasten electrical wiring harness (1) to rotating frame using detent strap (3) as shown.

To do so, guide detent strap (3) through sheet metal opening (arrow K) and fasten. i

Retaining clip (5), which is located on the electrical wiring harness (1), is not used and therefore also integrated.

7

Fasten detent strap (6) to electrical wiring harness (1).

To do so, keep both branch-off lines of yellow and white plug on electrical wiring harness (1) taut and parallel to each other, and fasten together with detent strap (6).

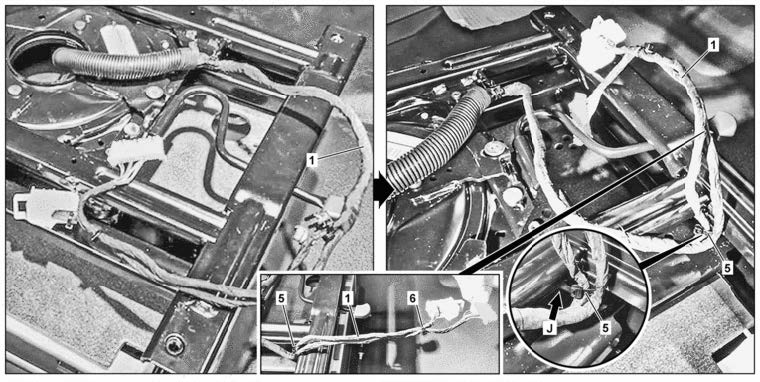

Vehicles with code SR8 (Driver’s seat rotating frame) and code SF1 (Electrically adjustable driver’s seat)

Steps 8 to 10 are to be performed on vehicles equipped with code SR8 (Driver’s seat rotating frame) and code SF1 (Electrically adjustable driver’s seat).

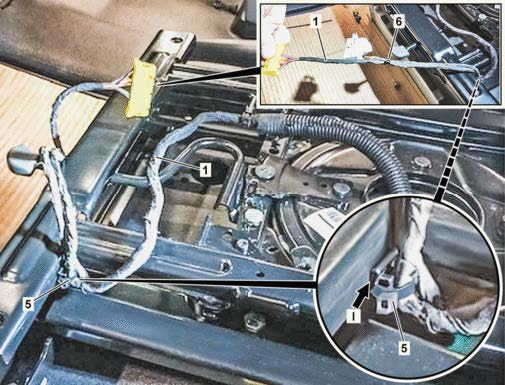

Shown with code SR8 (Driver’s seat rotating frame) and code SF1 (Electrically adjustable driver’s seat)

1 Electrical wiring harness

5 Mounting clip

6 Detent strap

8

Check whether electrical wiring harness (1) is fastened to central passage in rotating frame with retaining clip. If not fastened,

↓

secure electrical wiring harness (1) to central passage using retaining clip.

9

Fasten electrical wiring harness (1) to rotating frame using existing retaining clip (5) as shown.

To do so, slide retaining clip (5) from below onto rotating frame (arrow I) as shown.

10

Fasten detent strap (6) to electrical wiring harness (1). i

To do so, keep both branch-off lines of yellow and white plug on electrical wiring harness (1) taut and parallel and fasten together with detent strap (6).

| SM91.10-D-0032-02SGC | Perform modification of line installation of rotating seats (code: VS3DREHSIK, acc. no.: 91 902 58) | |

| Topical note | Notes on carrying out repair work in the vehicle interior | AH68.00-N-0001-01S |

Vehicles with SR9 (Front passenger seat rotating frame)

Perform steps 1 to 3 on vehicles that are only equipped with code SR9 (Front passenger seat rotating frame).

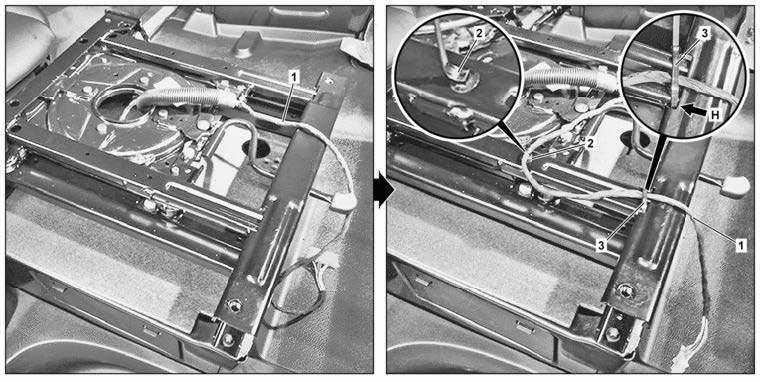

Shown with code SR9 (Front passenger seat rotating frame)

1

Check whether electrical wiring harness (1) is fastened to central passage in rotating frame with retaining clip.

If not fastened,

↓

secure electrical wiring harness (1) to central passage using retaining clip.

Pull electrical wiring harness (1) taut and fasten to retaining clip (2).

2

Fasten electrical wiring harness (1) to rotating frame using retaining clip (2) as shown.

To do so, clip retaining clip (2) onto rotating frame as shown.

To do so, guide detent strap (3) through sheet metal opening (arrow H) and fasten.

3

Fasten electrical wiring harness (1) to rotating frame using detent strap (3) as shown.

Vehicles with code SR9 (Front passenger seat rotating frame) and code H15 (Seat heating for front passenger)

Steps 4 to 7 are to be performed on vehicles equipped with code SR9 (Front passenger seat rotating frame) and code H15 (Seat heating for front passenger).

Shown with code SR9 (Front passenger seat rotating frame) and code H15 (Seat heating for front passenger)

4

Check whether electrical wiring harness (1) is fastened to central passage in rotating frame with retaining clip. If not fastened,

↓

secure electrical wiring harness (1) to central passage using retaining clip.

5

Fasten electrical wiring harness (1) to rotating frame using retaining clip (2) as shown.

To do so, guide detent strap (3) through sheet metal opening (arrow K) and fasten.

To do so, clip retaining clip (2) onto rotating frame as shown.

Keep electrical wiring harness (1) taut and fasten to retaining clip (2).

6

Fasten electrical wiring harness (1) to rotating frame using detent strap (3) as shown.

To do so, keep both branch-off lines of yellow and white plug on electrical wiring harness (1) taut and parallel and fasten together with detent strap (6).

7

Fasten detent strap (6) to electrical wiring harness (1).

Vehicles with code SR9 (Front passenger seat rotating frame) and code SF2 (Electrically adjustable front passenger seat)

Steps 8 to 10 are to be performed on vehicles equipped with code SR9 (Front passenger seat rotating frame) and code SF2 (Electrically adjustable front passenger seat).

Shown with code SR9 (Front passenger seat rotating frame) and code SF2 (Electrically adjustable front passenger seat)

8

Check whether electrical wiring harness (1) is fastened to central passage in rotating frame with retaining clip. If not fastened,

↓

secure electrical wiring harness (1) to central passage using retaining clip. 9 Fasten electrical wiring harness (1) to rotating frame using existing retaining clip (5) as shown.

To do so, slide retaining clip (5) from below onto rotating frame (arrow J) as shown.

10

Fasten detent strap (6) to electrical wiring harness (1).

To do so, keep both branch-off lines of yellow and white plug on electrical wiring harness (1) taut and parallel and fasten together with detent strap (6).

IMPORTANT SAFETY RECALL #2020070011

This notice applies to your vehicle, VIN: WD3PE7CC0

Check Front Swivel Seat Wiring Harness

NHTSA Recall #20V322

August, 2020

2020070011

WD3PE7CC0

- A safety defect exists in your vehicle

- Schedule an appointment with your authorized Freightliner Sprinter dealer as soon as possible.

- This repair will be provided free of charge.

Dear Freightliner Sprinter Owner,

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act.

Mercedes-Benz AG (“MBAG”), the manufacturer of Freightliner Sprinter vans, has decided that a defect which relates to motor vehicle safety exists in certain Model Year 2019-2020 Freightliner Sprinter vehicles. Our records indicate that your vehicle is included in the affected population of vehicles.

| What is the CONCERN? | On certain Sprinter vehicles that are equipped with front swivel-seats, the wires in the seat wiring harness could become jammed and damaged in the swivel-seat frame. In that case, the operation of the side airbag within the driver and/or front passenger seats seat could be adversely affected, which could cause the side airbag to deploy inadvertently or not deploy as designed in the event of a crash, increasing the risk of injury to vehicle occupants. |

| What will your DEALER DO? | An authorized Freightliner Sprinter dealer will inspect the routing of the front seat (left/right) seat wiring harnesses of the and will repair as necessary. This service will be provided free of charge. While the minimum repair time is approximately 2 hours, your dealer can provide you with a better estimate of the overall time for this service visit. As a matter of normal service process, an authorized Freightliner dealer will also check for other repair measures which might be applicable to your vehicle and this may increase the required working time. You will not be charged for other service or repairs unless so requested. |

Please schedule an appointment at your preferred authorized Freightliner Sprinter Dealer.

A VIN-based recall lookup tool on our website offers a search feature that will indicate whether a vehicle has been subject to a safety recall, and whether that vehicle has had the free remedy performed. See www.freightlinersprinterusa.com/freightliner/owners-resources/recall. Please mention you are scheduling an appointment to inspect the routing of the seat wiring harness under Recall Campaign # 2020070011. You may be asked for your 17-digit Vehicle Identification Number (VIN) which for your convenience is located above your name at the top of this letter.

We encourage you to sign up for recall alerts at www.nhtsa.gov/alerts. In the event that you are no longer the vehicle owner, or have had a change of address, please complete the reverse side and return the updated information in the enclosed envelope.

If this is a leased vehicle and the lessor and registered owner receive this notice, please forward this information by first class mail to the lessee within 10 business days to comply with Federal Regulations.

Should you have any questions difficulty regarding this Recall Campaign, please contact an authorized Freightliner Sprinter dealer. If for any reason a dealer is unable to remedy your situation, we are always happy to hear from you. Please contact us at 1-877-762-8267.

If an authorized Freightliner dealer for any reason is unable to remedy the situation without charge, or within a reasonable amount of time, pursuant to law 49 U.S.C. Chapter 301, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue, S.E., Washington, D.C. 20590 or call the toll-free Auto Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153); or go to https://www.safercar.gov.

We apologize for any inconvenience this situation may cause you, but your safety is of utmost concern to Freightliner.

Sincerely,

Daimler Vans USA, LLC

One Mercedes-Benz Drive

Sandy Springs, GA 30328

Phone (770) 705-0600

IMPORTANT VIN:

If for any reason YOU NO LONGER OWN THIS VEHICLE OR have a CHANGE OF ADDRESS, please COMPLETE THE SECTION BELOW, place in the ENCLOSED ENVELOPE, and DROP IN ANY MAIL BOX. If possible, provide the name and address of the present owner so that we may contact them.

Chronology of Defect (too many characters for the recall portal comment box)

Chronology:

In March 2019, a production plant in Germany identified that the front seat wiring harness on an individual vehicle was not secured in place as expected.

A first technical evaluation in March 2019 did not identify the risk of pinching damage to the wiring harness and, therefore, impact to the SRS system was not identified at that time.

After investigation, additional clips and route guiding were introduced into the production plants in June/July, 2019.

An additional improvement was made in October 2019, to introduce an extended wiring harness that could provide additional flexibility in the cable to move along with the seat. Moreover, additional instructions for the correct mounting of the wiring harness were provided for production.

Further investigation revealed that Mercedes-Benz had received about 33 field inputs with regard to the front seats and/or the electrical system, including some from the United States market. Field reports were received starting in the second half of 2019 and were generally received early in the life of the vehicles (3-6 months).

Mercedes-Benz continued to investigate under what circumstances the SRS indicator lamps could illuminate and the potential consequences for vehicles equipped with front swivel seats. This included consideration of the potential impact on multiple functions, including impact on driver assistance systems, occupant sensing systems, seat belt reminders, side airbags and electrical seat adjustment or heating. The cable routing system requires a complex balance of ensuring flexibility to allow seat movement and effecting the security of the wire harness system itself.

Investigations were also focusing on potential consequences from certain lines of the complex wiring harness becoming pinched individually or in combination at the same time.

MBAG’s investigation continued into 2020. Due to the COVID-19 pandemic, plants were shut down and many employees were furloughed during the spring of 2020. Nonetheless, MBAG was able to isolate the cause of the electric failures in the field. This included the cases where illumination of the SRS indicator lamp occurred due to a disruption in the signals to the side airbag, which could lead to the side airbag either deploying inadvertently or not deploying as required. MBAG is unaware of any such incidents having occurred either in the US or elsewhere.

On May 27, 2020, MBAG determined that a safety risk could not be ruled out and decided to initiate a recall campaign.

2 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| FREIGHTLINER | SPRINTER (VS30) | 2019 |

| MERCEDES BENZ | SPRINTER (VS30) | 2019 |

13 Associated Documents

Miscellaneous Document- Supplemental Chronology

RMISC-20V322-4951.pdf 598.534KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

RCMN-20V322-8326.pdf 299.861KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-20V322-6624.PDF 215.892KB

Loading...

Loading...

Recall Acknowledgement

RCAK-20V322-8829.pdf 244.945KB

Loading...

Loading...

Recall 573 Report- Amendment 1

RCLRPT-20V322-2420.PDF 215.862KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

RCMN-20V322-2517.pdf 1841.162KB

Loading...

Loading...

ISSUED Interim Owner Notification Letter(Part 577)

RIONL-20V322-7506.pdf 163.203KB

Loading...

Loading...

Recall Quarterly Report #1, 2020-3

RCLQRT-20V322-1561.PDF 211.15KB

Loading...

Loading...

Recall Quarterly Report #2, 2020-4

RCLQRT-20V322-8109.PDF 211.253KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-20V322-6782.pdf 105.098KB

Loading...

Loading...

ISSUED Interim Owner Notification Letter(Part 577)

RIONL-20V322-4657.pdf 92.506KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-20V322-7757.pdf 189.998KB

Loading...

Loading...

Recall Quarterly Report #3, 2021-1

RCLQRT-20V322-3068.PDF 211.34KB

Loading...

Loading...

Latest Recalls Documents

https://www-odi.nhtsa.dot.gov/acms/cs/documentList.xhtml?docId=20V322&docType=RCL

| “This site contains affiliate links for which OEMDTC may be compensated” |

- 【Zip Ties Packing Including】HAVE ME TD Zip Ties Total:400pcs Cable Zip Ties.4inch X 100pcs,6inch X 100pcs,8inch X 100pcs,12inch X 100pcs.Each size cable tie has a wide range of uses,suit for multiple purpose projects in different situations.

- 【Cable Ties Loop Tensile Strength】Loop tensile strength: 4inch-18lbs,6inch-40lbs,8inch-40lbs,12inch-40lbs.This pack of cable ties comes with assorted sizes cable ties for a wide range of personal and professional needs.Cable ties of different sizes and tensile strength are suitable for multi-purpose projects on different occasions.

- 【Black Zip Tie Self-locking Design】HAVE ME TD zip ties self-locking fastener design,strong durable powerful lock,easy handling and prevent snagging in tight. With cable zip, cables can be tied tightly. Cable ties can be very flexible with high temperature resistance.

- 【Multiple purpose Zip Ties】 Perfect Choice for home, office, garden,garage, travel and workshop tidy.HAVE ME TD cable zip ties are the perfect choice for many indoor & outdoor projects like organizing electrical wires, hanging lights and banners, attaching garden fences/ net, plants,securing bike/ car accessories and much more.

- 【Zip Ties Black】Whenever you need sort out your different wires, zippers and other accessories,it's a good choice.Meet your different size requirements.No need to waste time to find different size cable ties.If you have any questions, please contact us by HAVE ME TD, we will help you solve the problem as soon as possible.

- Great Value: Those zip ties are great value for price, can be used in light-weight applications with 40lbs tensile strength.

- Dimensions: Length: 8" | Width : 0.14" | Max Dia: 2" |Tensile Strength: 40lbs | Color: Black | Quantity: 100 Pack.

- Indoor and Outdoor Use: With various applications for home, shed, garden, garage, organizing electrical cable ties.

- High Quality Material: Plastic ties are made of nylon66, can be used in temperature from -40℉ to 185℉, weather and UV resistant.

- Warranty: Our zip ties have a 1-year warranty period. Customer will receive a 100% refund if any quality issue under warranty period.

- 4 Diff Sizes: 4", 18 lb | 6", 25 lb | 8", 40 lb | 12", 45 lb.

- 400 Pack: 4", 100 Pack | 6", 100 Pack | 8", 100 Pack | 12", 100 Pack.

- Multi-purpose Use: Multiple sizes and tensile strength are suitable for various situations.

- Indoor & Outdoor: Perfect for home, office, garden, garage, organizing electrical wires, hanging lights, attaching fences, etc.

- Warranty: Customer will receive a 100% refund if any quality issue.

- 100 Pack: Multi-Purpose, UV Stabalized Heavy Duty Cable Ties suitable for a wide range of Indoors & Outdoors use.

- Built for Performance with Narrow Design: 18 Lbs Tensile Strength | Length 8" | Width 0.10" | Max Dia 2" | Color: Clear White

- Durable & High Quality: Self-locking nylon 6/6 plastic zip ties are made with temper proof lock. Working temparture ranges from -13℉ to 185℉

- Infinite Use: Robust fastener tool great for home, shed, garden, garage, organizing electrical cable, wreath making, decorations etc. Works in wet and/or Dry projects. Popular among businesses.

- Unparallel Collection: With the largest cable tie collection in North America, find the perfect size and variation to suit your project's needs on our Amazon Store.

- Infinite Applications - Zip ties are one of the most versatile tools in the world. You can use cable ties to secure cables, wires, bundle decorations, or even hang garden plants, we've got the perfect solution for you!

- Premium Quality - Zip ties heavy duty are made of high quality industrial strength 6/6 nylon to ensure extended durability and they have a tensile strength of up to 40 lbs. Heavy duty zip ties are weather resistant and can withstand the harshest weather conditions (operating temperatures of -40°F to +185°F).

- Self-Locking Design - Each white zip tie has a durable self-locking mechanism that locks very securely and will not budge over time, and the locking teeth stop the cable tie at the desired length. Easy to use and straight to the point.

- Easy To Use - The clear zip ties tail curves to ensure easy head insertion and smooth edges for quick and smooth tightening.

- What You Get - Pack of 100 pcs Boacua zip tie ( L: 300mm/12in, W: 4.5mm/0.18in), 100% satisfied replacement if quality issue and delivery damaged.

- 100 Pack: With 100 zip ties in each package, you don't have to worry about running out of in the middle of your project.

- Dimensions: Length: 14" | Width : 0.19" | Max Dia: 4" |Tensile Strength: 50lb | Color: Black | Quantity: 100 Pack.

- High Quality Material: Plastic ties are made of nylon66, can be used in temperature from -40℉ to 185℉, weather and UV resistant.

- Indoor or Outdoor Use: With various applications for home, shed, garden, garage, organizing electrical cable ties.

- Warranty: SKALON zip ties 14 inch have a 1-year warranty period. Customer will receive a 100% refund if any quality issue under warranty period.

- Light & medium duty white cable tie and black zipties for garden, home, office, garage, workshop and more

- Indoor and outdoor use wire ties are designed with rounded edges to provide easy handling and prevent snagging in tight spaces

- Durable single-use plastic ties are rated with a 17 lb or 48 lb tensile strength; Increase the tensile strength by using two or more together in a row

- Cost-effective 200-pack of cable ties for many uses; Comes in a re-sealable container for convenient storage

- Nylon zip ties assorted sizes are constructed with fire resistant materials; Locking teeth in the white and black tie wraps head secure cables or wires

- 📌【Cable Ties Loop Tensile Strength】Loop tensile strength 50lbs.Cable ties tensile strength are suitable for multi-purpose projects on different occasions,Increase the tensile strength by using two or more together in a row,Cost-effective 100-pack of cable zipties for many uses; Comes in a re-sealable container for convenient storage.

- 📌【Upgrade Materials】Made of industrial strength nylon 66 fire-resistant material (fire rating 94V-2). It has high toughness, aging resistance, corrosion resistance, aging resistance, UV resistance, and good insulation. The excellent performance ensures their safe use, even when cables or other objects are inadvertently heated. It can be used in the temperature range of -40°F to +185°F (-40°C to 85°C) and outdoor in direct sunlight application is not an issue.

- 📌【Zip Ties Assorted Sizes】Our store offers a variety of colors and sizes to meet your needs. These assorted cable ties are an excellent tool for home, office, garden, garage, travel and workshop organization. You can use it to manage cables, wires, and cords to keep them organized. It can also be used to fixing plants, bundling light strips, hanging curtains, Christmas decoration, etc.

- 📌【Multiple Purpose Zip Ties】These assorted cable ties are an excellent tool for home, office, garden, garage, travel and workshop organization. You can use it to manage cables, wires, and cords to keep them organized. It can also be used to fixing plants, bundling light strips, hanging curtains, Christmas decoration, etc.

- 🎁【After-Sales Service】Our swift exchange policy enables you to purchase without hesitation! 100% satisfaction guaranteed, Free lifetime return and exchange policy.When you have a problem in using the cable zip ties, please contact us and our customer service team will reply you and provide technical support within 24 hours.

- 【Heavy Duty】 Strength tensile is decided by Width-- Our wire ties 0.14inch / 3.5mm wider make the ties stronger than the same size for more projects.

- 【High Quality Material】 Made of industrial strength nylon 6/6 fire resistant material, and can be used in temperatures ranges from 040F to +185F (440C to +85C), weather resistant and outdoor in direct sunlight application is not an issue.

- 【Self-locking】 Self-locking Fastener Design, Strong tough powerful lock, easy handling and prevent snagging in tight.

- 【Details】100-PACK of strong plastic cable ties usable in many applications , 8" in length with black color.

- 【Guarantee】 All our products come with a Lifetime warranty. Hmrope will make sure that you will be satisfied with it. For any reason if you don't like. You will receive a full refund. try it, totally risk free! click add to cart now!

- PACKAGE CONTAINS: 100 long, UV resistant nylon zip ties

- SIZE: 14" x 0.19" (50lb Strength)

- COLOR: White/Clear

- BUILT TO LAST: Made of industrial strength nylon 6/6, GTSE zip ties are able to withstand even the toughest weather conditions (working temperature -40°F to +185°F). Each zip tie features a durable self-locking mechanism which doesn't falter over time.

- LIMITLESS APPLICATIONS: Perfect for home DIY, commercial purposes, cable management and gardening. Our zip ties are proudly used by households, contractors and industry all over the world!

Last update on 2024-06-18 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.