| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10174934

Manufacturer Communication Number: ENP-733

Summary

The Agility Fuel Solutions (Agility®) service team identified two fuel system ECU (electronic control unit) calibration issues in Blue iQ CNG (compressed natural gas) fuel systems for the Cummins® 6.7L engine. Issue 1: Program incompatibility causes throttle response to drop to zero when an attempt is made to operate in economy (Eco) mode. Issue 2: “Liters to Empty” Smart Gauge function is not programmed; at fuel levels less than 5-10%, zero throttle response results. Agility® is coding a new ECU calibration to remedy these conditions which will be distributed through the Cummins INSITE customer online portal.

3 Affected Products

Equipments

| BRAND | PART NO. | PRODUCTION DATES |

| AGILITY FUEL SYSTEMS | CNG FUEL SYSTEM | |

| AGILITY FUEL SYSTEMS | CNG FUEL TANK | |

| AGILITY FUEL SYSTEMS | CNG PRESSURE RELIEF DEVIC | |

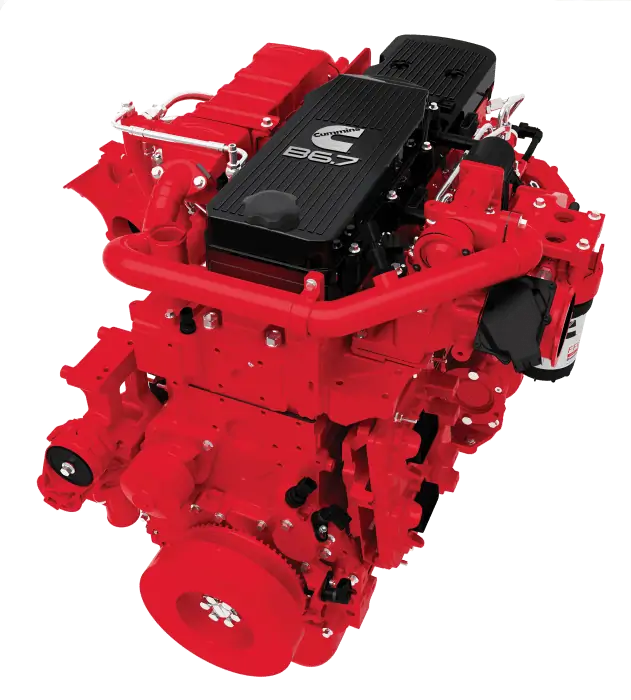

Blue iQ Cummins B6.7L CNG

De-rate and Hours to Empty Calibrations

ENP-733

April 27, 2020

1. Introduction

The Agility Fuel Solutions (Agility®) service team has identified two fuel system ECU (electronic control unit) calibration issues in Blue iQ CNG (compressed natural gas) fuel systems for the Cummins® 6.7L engine as follows:

Issue 1: Program incompatibility causes throttle response to drop to zero when an attempt is made to operate in economy (Eco) mode.

Issue 2: “Liters to Empty” Smart Gauge function is not programmed; at fuel levels less than 5-10%, zero throttle response results.

Agility® is coding a new ECU calibration to remedy these conditions which will be distributed through the Cummins INSITE customer online portal.

Effective immediately and continuing until affected units receive the new calibration, Agility® recommends the following precautionary measures:

- Do not operate the vehicle in Eco mode, and

- Do not rely on the Liters to Empty Smart Gauge function; always keep the vehicle well-fueled to avoid an unexpected empty condition.

2. Affected Units

Two Autocar (VINs 232122 and 232123) and 52 TICO yard tractors equipped with Agility® Blue iQ CNG fuel systems and Cummins® 6.7L engines.

3. Tools Required

4. Diagnostic Symptoms and Preventative Measures

Issue 1: Zero throttle response when Eco Mode is enabled. Figure 1

Figure 1.

Smart Gauge green LED (1) illuminated and “Eco Mode Enabled” message (2) displayed.

ACTION: Press and hold the right Smart Gauge function button until the display changes to

“Eco Mode Disabled” and the red LED illuminates to disable Eco Mode. Figure 2

Figure 2.

Smart Gauge right function button (3), red LED (1) illuminated, and “Eco Mode Disabled” message (2) displayed. The Smart Gauge should display “Eco Mode Disabled” during unit operation until the ECU calibration update is released. Figure 2

Issue 2: Zero throttle response at low fuel levels less than 5-10%.

Figure 3.

Smart Gauge red LED (1) illuminated and “Derate Active” message (2) displayed.

ACTION: Unit must refuel to disable the derate condition automatically.

ALTERNATIVE ACTION: Temporarily disable derate by holding down the Override button; this allows units to be operated on CNG pony tanks.

5. Corrective Action / Procedure

Issues 1 and 2: Install new Agility® ECU calibration, software version TBA via Cummins® INSITE using the following procedure:

Step 1: Using either a NEXIQ® USB-Link 2 or Cummins® INLINE7 tool, verify OBD-II connection is correctly selected. Figure 4.

NEXIQ tool programming screens (not shown throughout this procedure) are similar.

Step 2: Click “Connect to ECM” from the left tab menu. Figure 4

Figure 4.

Initial programming screen. INLINE7 tool connection verification (1) and Step 2 “Connect to ECM” (2).

Step 3a: Click “Connect.” NOTE: No security type or password credentials are required. Figure 5

Step 3a – “Connect” button.

Step 3b: Select “Agility Fuel Delivery System [18]” and click “Connect.” Figure 6.

Figure 6.

Step 3b – “Agility Fuel Delivery System [18]” and “Connect” button.

Step 4: Click “New” and “OK” on the pop-up menus. Figure 7

Step 4 – “New” and “OK” buttons.

Step 5: Once connected, verify ECM connection at the bottom left of the window. Figure 8

Figure 8.

Step 5 – Green circle indicates tool is connected to the ECM.

Step 6: Click “Calibration Selection” from the left tab menu. Figure 9

Figure 9.

Step 6 -“Calibration Selection” tab (6) and Step 7 “ECM/PDD Code Search” button (7).

Step 7: Click “ECM/PDD Code Search” button (Figure 9) and the “Checking for calibration updates” screen will appear. Figure 10

Figure 10.

Step 7 – Checking for calibration updates screen.

Step 8: Wait for a “Successfully found (CAL ID tba)” message to appear in the status box.

When the desired calibration is found, click “Save” and proceed to Step 9. Figure 11

Figure 11.

Step 8 – “Successfully found (CAL ID tba)” message in Status box (a) and “Save” button (8).

The following screen will appear if the requested calibration is not found (Figure 12):

Figure 12.

Step 8 – Calibration not found screen.

If the calibration was not found, double check the following connections:

- Verify stable Wi-Fi signal is present

- Confirm NEXIQ® USB-Link 2 or Cummins® INLINE7 tool is connected to OBD-II

- Confirm Agility ECU is connected properly to the fuel system chassis harness Repeat Steps 6 through 8.

Step 9: Click the “Exit” button. Figure 12

Step 10: Click the “ECM/PDD” button, add all, and click on the “OK” button. Figure 13

Figure 13

Step 10 “ECM/PDD” button (10).

When these options appear, select “Add All,” and click on the “OK” button.

Step 11: Click/expand all folders (the + buttons), then click on “4354537.” Figure 14

Figure 14

Select “Add All” and click “OK.” Figure 15

Figure 15

Step 11b. “Add All” and “OK” buttons (11b).

Step 12: Right click on the calibration ID #, then click “Transfer to ECM” in the pull down menu. Figure 16

Figure 16.

Step 12. Select desired Cal ID # from the list, then click “Transfer to ECM” (12).

Step 13: Follow prompts until programming is successful/complete.

Step 14: When complete, click “Disconnect from ECM” tab at upper left menu and close out INSITE. Figure 17

Figure 17. Step 14 Disconnect from ECM tab.

6. Warranty Information

This procedure is covered under warranty. Standard repair time (SRT) is 0.5 hours. Please refer to Warranty Manual, ENP-067, for warranty reimbursement procedures.

For parts and support, contact Agility® Customer Care: +1 949 267 7745, toll free: +1 855 500 2445 or parts@agilityfs.com

Agility Fuel Solutions | 3335 Susan Street Suite 100 | Costa Mesa, CA 92626 USA www.agilityfuelsolutions.com

| Revision | Description | Date |

| — | Initial Release | 04/27/2020 |

ENP-733

April 27, 2020

https://www.nhtsa.gov/recalls?nhtsaId=10174934

https://static.nhtsa.gov/odi/tsbs/2020/MC-10174934-9999.pdf

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- 【TWO MODES】: The 1/2 PSI gas regulator have both propane and natural gas mode. The factory setting of the nature pressure regulator is propane mode, if you need natural gas mode, please open the knob on the cover to convert the screw to natural gas mode, please refer to our picture for details.

- 【SPECIFICATIONS】:The therad on the Regulator is 1/2" Male Thread and the end of house is 3/8" Female Flare. When using LPG regulating valve: LP inlet pressure is 2.74Kpa(11 "w.c), outlet pressure is 2.45~2.55 kpa(10 "w.c), gas flow rate is 30L/min; When using natural gas regulating valve: LP inlet pressure is 1.74Kpa(7 "w.c). Outlet pressure is 0.95~1.05 kpa(4 "w.c), flow rate is 50L/min.

- 【FUNCTIONS】: This 102-B model rugulator converts your equipment that uses propane to one that uses natural gas. You can use it to replace the Kitchen Aid Natural Gas Conversion Kit 710-0003.Functions the same as the original part contents.

- 【CONVERSION MODEL】: This natural gas pressure regulator can converts these KitchenAid grill models to NG: 720-0709, 720-0709B, 720-0709C, 720-0733, 720-0733A, 720-0745, 720-0745A, 720-0745B, 720-0787, 720-0787D, 720-0819, 720-0819A, 720-0891B, 720-0826, 720-0891R, 720-0893.

- 【WARM TIPS】: The natural gas conversion Kit is rated to operate from -32°F to 225°F (0°C to 107°C) Do not install the regulator too close to heating equipment or use it in very cold environments. Heat and cold will change the resistance of the spring inside the regulator. The gas pressure regulator will not shut off the gas flow.

- ❤ Same as Origina Replacement Parts of Kitchen Aid NATURAL GAS CONVERSION KIT 710-0003 Natural Regulator Inside Not Including the Qucik Connect Hose. 𝐓𝐡𝐞 𝐏𝐫𝐞𝐬𝐞𝐭 𝐨𝐟 𝐠𝐚𝐬 𝐢𝐬 𝐟𝐨𝐫 𝐋𝐏 𝐏𝐫𝐨𝐩𝐚𝐧𝐞, If you want to use for Natural, Please adjust the top of regulator according our description steps by hand.

- ❤ This conversion kit turns your KitchenAid liquid propane grill into a natural gas grilling machine by swapping out the existing components with an NG regulator and your current Natural hose.

- ❤ Converts these KitchenAid grill models to NG: 720-0709, 720-0709B, 720-0709C, 720-0733, 720-0733A, 720-0745, 720-0745A, 720-0745B, 720-0787, 720-0787D, 720-0819, 720-0819A, 720-0891B, 720-0826, 720-0891R, 720-0893

- ❤ Converts your dual-gas propane grill to natural gas ( You need an existed Natural Hose to Use with this NG Regulator Kit) . The Regulator is Adjustable. When the LPG gas regulating valve is used: LP inlet pressure is 2.74Kpa(11"w.c), outlet pressure is 2.45~2.55 kpa(10"w.c), and gas flow rate is 30L/min; When the natural gas regulating valve is used: LP inlet pressure is 1.74Kpa(7"w.c). Outlet pressure is 0.95~1.05 kpa(4"w.c), flow rate: 50L/min

- ❤ The 1/2 PSI gas regulator of the 102-B model is compatible with natural gas and liquefied gas valves. The Fitting on the Regulator with 1/2" Male Thread and1/2" Female Flare Fittings on the Hose.(Thread size standard 3/4"-16UNEF)

- 【Brand New】100% Brand New and All parts are tested and quality controlled prior to shipment

- Fitment: Fits For Ford Lincoln Mercury Vehicles with 2.0 2.3 3.0 3.8 3.9 4.6 5.4 Liter V6 V8 L4 Engine : For 2004 2005 Ford Explorer; For 2003 2004 Ford Crown Victoria; For 2004 2005 2006 2007 2008 Ford F150; For 2000 2001 2002 2003 2004 Ford Focus; For 2005 2006 Ford E150 Club Wagon E250 GT; For 2002 2003 2004 2005 2006 2007 Ford Taurus Thunderbird.

- Fitment: Fits For 1999 2000 2001 2002 2003 2004 Ford Mustang; For 2003 2004 2005 2006 Lincoln Town Car Aviator; For 1998 1999 2000 2001 2002 Lincoln Continental; For 2000 2001 2002 2003 2004 2005 2006 Lincoln LS; For 1998 1999 Mercury Tracer; For 2002 2003 2004 Mercury Sable Marauder Mountaineer Grand Marquis

- Manufacturer Part Number:FPS7, 3R3Z-9F972-AA, 3R3Z-9F972-AB, 3R3Z9F972AA, FPS-7; 3R3Z9F972AB, 3R3E-9F972-AA, F8CZ-9F972-BD, F8CZ-9F972-BC; F8CZ-9F972-BE, 3R3E9F972AA, F8CZ9F972BD, F8CZ9F972BC;XW4Z-9F972-BA, XW4Z9F972BA, 3R3Z-9G756-AC, F8CZ9F972BE; 3R3Z9G756AC, F8CF9F972BG, F8CF9F972BE, F8CF9F972BH; F8CF9F972BF, F8CF-9F972-BE, F8CF-9F972-BH;FPS17, FPS-507, F8CF-9F972-BF, F8CF-9F972-BG;PR244, SU10479, SU13804, 5G1142, 5S9017, FPS507, FPS-17.

- Package Include:1x Fuel Pressure Sensor

- Perfect Fit: Fit for Kitchen-Aid 710-0003, fit for 720-0709 720-0709B 720-0709C 720-0826 720-0893 720-0819B 720-0745B 720-0745 720-0745A 720-0787D

- Multifunctional Compatibility: This regulator fits various grill models and can easily convert your liquid propane grill to a natural gas grill. Before purchasing, confirm with your grill supplier if you need to replace the orifice

- High-Quality Brass: Made with safe and reliable materials, our natural gas converter is not easily broken or deformed, works better, and lasts longer

- Easy to Install: Equipped with a 3/8 "Female Flare by 1/2" Male Flare Brass Adapter, this converter is easy to install. Just connect it to your grill and dial in your desired temperature

- What's Included: 1 x natural gas converter. If you have any problems with the products you received, please contact us in time

- 【Brand New】100% Brand New and All parts are tested and quality controlled prior to shipment

- For 2004-2005 Ford Explorer Sport Trac 4.0L

- Interchange Part Numbers - 3F2Z9F792CA, 3F2Z9G756AA, 3F2Z9G756AB, 3F2Z9G756AC, 3F2Z9G758AC, SU8744, 0261230094, 0 261 230 094, 2260004, 0 261 230 093, 5S7254, PA66-GF30, 3F2E9G756AD, 3F2E-9G756-AD, FPS505, CM5226, CM5229, CM-5229, CM-5226, 0261230093, 4490313, BU5Z9F972A, FPS-5, FPS5

- Direct replacement for a proper fit and easy installation, just plug and & play

- Package Include:1 x Fuel Injection Pressure Regulator Sensor

- MATERIAL: made of - material.

- QUALITY: it meets strict quality control standards.

- DURABLE: durable, not easy to damage and long life.

- INSTALLATION: Easy installation and replacement,the damaged can be easily replaced.

- REPLACEMENT: Reliable replacement accessories, stable and has high reliability.

Last update on 2024-06-12 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.