| “This site contains affiliate links for which OEMDTC may be compensated” |

June 21, 2019 NHTSA CAMPAIGN NUMBER: 19V486000

Loss of Hydraulic Assist Steering

Loss of hydraulic assist steering may make it difficult to steer the vehicle, increasing the risk of a crash.

NHTSA Campaign Number: 19V486

Manufacturer Oshkosh Corporation

Components STEERING

Potential Number of Units Affected 72

Summary

Oshkosh Corporation (Oshkosh) is recalling certain 2018-2019 S-Series Mixer vehicles equipped with Cummins X12 engines with two hydraulic lines. The hydraulic hoses may have been unintentionally switched and installed to the wrong location, which can cause a loss of hydraulic assist steering.

Remedy

Oshkosh will notify owners, and Oshkosh S-Series Service will correct any improperly installed hoses, free of charge. The recall began August 12, 2019. Owners may contact Oshkosh customer service at 1-888-686-7278.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

SAFETY NOTICE

VSR-TSB-024

NHTSA Campaign Number: 19V-486

Vehicle Safety Recall – Technical Service Bulletin

PROMPT ACTION REQUIRED

| Attention: | Oshkosh Product Owner |

| Subject: | Hydraulic Steering Pump Hoses Routing Inspection |

| Models Affected: | Oshkosh S-Series Front Discharge Mixer |

| Model Year: | 2018-2019 |

| Date: | August 2019 |

Purpose:

A concern affecting safety exists in some Oshkosh S-Series Front Discharge Mixers. Trucks have been identified that are equipped with Cummins X12 engines with two hydraulic hardline routings that may have been connected incorrectly. Both hydraulic hose fittings are the same size so they may have been switched and installed to the incorrect location on the rear hardline assembly. If the hoses are switched, there is a possibility that the driver will have limited or no steering assist. This bulletin describes how to inspect for incorrect hose routing.

Important: Do not run or use the vehicle if the hoses are routed incorrectly. Contact S-Series Service Support at 888-686-7278 immediately.

Affected Vehicles:

The affected vehicle population is Oshkosh S-Series Front Discharge Mixers with Cummins X12 engines produced between 2018 and 2019. Please refer to the attached VIN list of affected vehicles.

Time Completion:

Complete the enclosed procedure for each affected truck. The time of accomplishment may vary due to a number of factors; however, the estimated time for completion of the procedure is 30 minutes under normal circumstances.

Required Action:

Review and verify your ownership of all affected serial numbers of Oshkosh vehicles. If Oshkosh records indicate that you are the owner of one or more affected trucks, a Serial Number List is enclosed. Please be reminded that it is a violation of Federal law for you to sell or lease the vehicles covered by this notification until this recall has been performed on these vehicles. Substantial civil penalties apply to violations of this law.

Reimbursement of Costs:

Affected trucks shall be inspected using the customer’s own qualified service technicians – at no cost to the owner. The inspection should take approximately 30 minutes.

Parts/Labor Reimbursement:

In order to receive credit, claims are to be submitted through the normal warranty claim system. Claims must be received within 30 days of the repair. Claims must include the Oshkosh VIN of the vehicle, the customer asset number, and the number of this bulletin.

Contacts:

If you have questions or need further information, please contact a McNeilus National Service Representative at 888-686-7278.

Enclosures:

Procedure

VIN List of Affected Vehicles

| SAFETY NOTICE |

| Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate. |

| SAFETY NOTICE |

| Use appropriate Personal Protective Equipment (PPE) as required by your company. |

PROCEDURE: Steering Pump Hose Inspection

Preparation and Inspection

Important: Do not run or use the vehicle if the hoses are routed incorrectly. Contact S-Series Service Support at 888-686-7278 immediately.

- Park vehicle on flat, level surface. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate. Chock wheels.

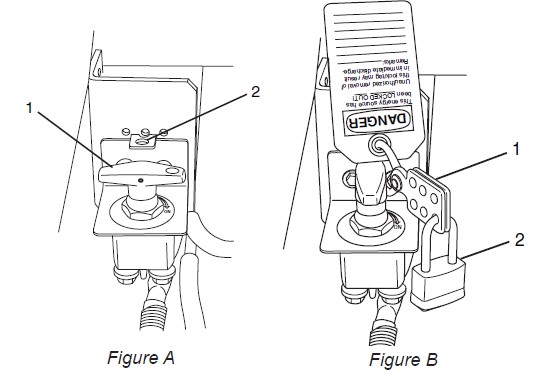

- Battery Disconnect Switch

If your vehicle is equipped with a BATTERY DISCONNECT switch, it is located near the battery box. Use the battery disconnect switch when performing any maintenance so the vehicle cannot accidentally be started.

-

- Turn the battery disconnect switch (Figure A, Item 1) counterclockwise so the hole on the switch aligns with the hole in the bracket (Figure A, Item 2).

- Install the safety lockout device ring (Figure B, Item 1) through the holes on the battery disconnect switch and the bracket.

- Install a padlock (Figure B, Item 2) onto the safety lockout device ring, lock it, and put the key in your pocket. If more than one person is working on the vehicle, each person must install his or her own padlock.

WARNING

For trucks without a battery disconnect switch, to prevent accidental vehicle start-up, which could cause death or serious injury, disconnect battery cables (negative cable first) before proceeding.

Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion, which could result in death or serious injury.

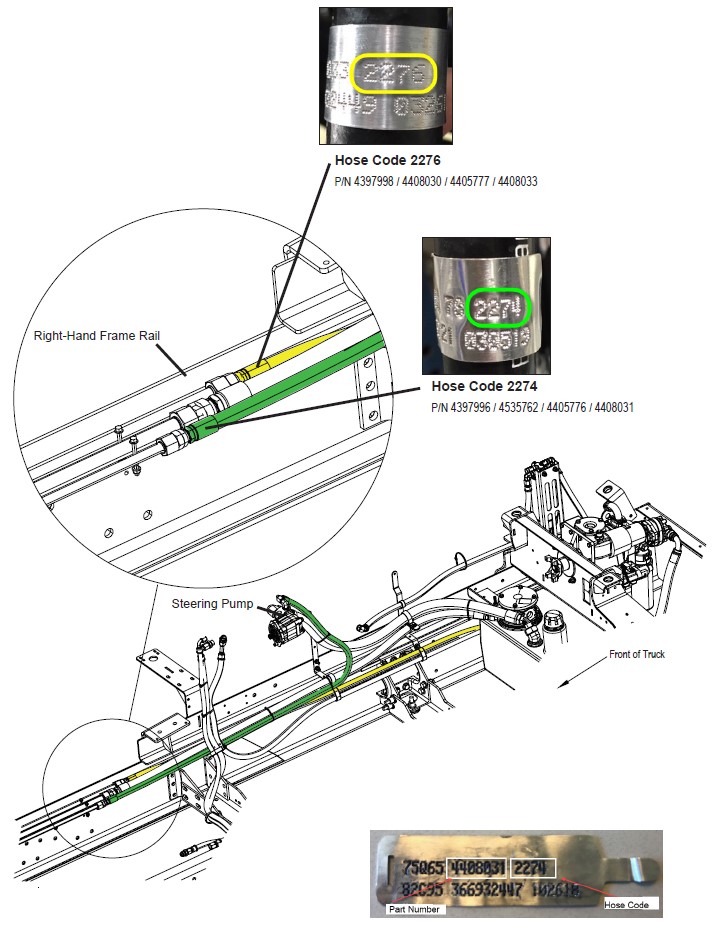

- Locate the three hardline to hose connections located on the right-hand side frame rail next to the transmission bell housing. See Figure 1. Use the aluminum code identification tags affixed to the hose to identify the hoses.

- Check that the hose closest to the right-hand frame rail has a “2276” hose code identification tag. Hose “2276” is shown in yellow in Figure 1.

- Check that the hose closest to the transmission bell housing has a “2274” hose code identification tag. Hose “2274” is shown in green in Figure 1.

Inspection Results and Actions

-

- If hoses 2274 and 2276 are installed correctly, this procedure is complete and no further action is required. Remove your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate. Remove the wheel chocks. Return the vehicle to service.

- If the hoses are incorrectly installed, Do not run or use the vehicle, maintain your company’s Lockout/ Tagout on the vehicle, and contact S-Series Service Support at 888-686-7278 immediately.

Figure 1

Hose Code 2276

P/N 4397998 / 4408030 / 4405777 / 4408033

Hose Code 2274

P/N 4397996 / 4535762 / 4405776 / 4408031

2 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

| OSHKOSH | S-SERIES | 2018-2019 |

8 Associated Documents

Recall 573 Report- Amendment 2

RCLRPT-19V486-6949.PDF 213.804KB

Loading...

Loading...

Recall Quarterly Report #2, 2019-4

RCLQRT-19V486-4759.PDF 211.22KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V486-7328.pdf 657.529KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-19V486-3542.PDF 213.774KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V486-6680.pdf 732.51KB

Loading...

Loading...

Recall Acknowledgement

Loading...

Loading...

Recall Quarterly Report #1, 2019-3

RCLQRT-19V486-1891.PDF 211.116KB

Loading...

Loading...

Recall Quarterly Report #3, 2020-1

RCLQRT-19V486-4836.PDF 211.302KB

Loading...

Loading...

Latest Recalls Documents

https://www-odi.nhtsa.dot.gov/acms/cs/documentList.xhtml?docId=19V486&docType=RCL

- Formulated with premium base stocks for added resistance to thermal breakdown

- Outstanding wear protection

- Excellent resistance to system rust and oil oxidation

- Maintains excellent water separating properties

- Excellent foam control and air release deliver consistent system operation

- Formulated with premium base stocks for added resistance to thermal breakdown

- Outstanding wear protection

- Excellent resistance to system rust and oil oxidation

- Maintains excellent water separating properties

- Excellent foam control and air release deliver consistent system operation

- Formulated with highly refined group ii base stocks for added resistance to thermal breakdown

- Superior wear protection to protect critical components

- Excellent frictional properties for smooth-shifting, excellent anti-shudder performance

- J20c equivalent, protection against varnish and sludge formation

- Superior thermal stability and oxidation resistance, good seal compatibility

- Meets and exceeds all OEM specifications for power shift transmissions

- Extends equipment and fluid life

- Reduces downtime and major overhaul

- Formulated with premium base stocks for added resistance to thermal breakdown

- Outstanding wear protection

- Excellent resistance to system rust and oil oxidation

- Maintains excellent water separating properties

- Excellent foam control and air release deliver consistent system operation

- Reduces the operating temperature of hydraulic systems

- Conditions old seals and O-rings to stop and prevent future leaks

- Well suited for use in equipment with wet brakes

- Removes varnish and restores pressure for more efficient operation

- Compatible with both synthetic and conventional hydraulic fluids

- MULTI-PURPOSE & ALL SEASON: A premium transmission-hydraulic fluid recommended for the complex lubrication systems of modern tractors, including industrial models. In these systems, the same lubricant may serve the hydraulic system, torque converter, transmission, power take-off, differential, power steering, and wet brakes.

- SPECIFICATIONS: Our tractor hydraulic fluid meets the following manufacturers specifications: (J20C, JD303), (Q-1826), (Improved power fluid 821XL), (ESN-M2C134-D, FNHA-2-C-201), (M1135, M1141, M1143), (Type 55), (JIC-143,144, 145, MS1206,127, 1209, 1210, TCH), (Fluids), (TO-2, MTD), (Bus Automatic Transmission Fluid), (UDT), (B6), (WB 101).

- APPLICATIONS: Included in the above applications, this universal tractor fluid also meets most other manufacturers' specifications for transmission hydraulic fluid. It can be used for makeup or refill in almost all tractor hydrostatic, hydraulic jack oil, transmission oil, differential fluid, and other systems involving common lube oil sumps.

- BENEFITS: This tractor transmission oil gives all-season protection. It flows readily at low temperatures due to its low-temperature viscosity and pour point, and yet retains its body at high temperatures due to a high viscosity index. Other benefits include anti-foam, anti-rust, anti-wear, extreme pressure, seal protection, oxidative and thermal stability, and controlled frictional characteristics.

- PREMIUM LUBRICANTS: Presidential Engineered Lubricants offers premium machine oils, lubricants, and sealants for various industries. Founded in 1877, we're an employee-owned company dedicated to crafting high-quality products at our UO facility, with customer satisfaction as our top priority.

Last update on 2024-06-10 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.