| “This site contains affiliate links for which OEMDTC may be compensated” |

April 13, 2018 NHTSA CAMPAIGN NUMBER: 18V237000

Hydraulic Cab Lift Hose Chaffing may cause Fire

A fluid leak combined with arcing between the power stud and the exposed wire can increase the risk of a fire.

NHTSA Campaign Number: 18V237

Manufacturer Kovatch Mobile Equipment Corp.

Components SERVICE BRAKES, HYDRAULIC

Potential Number of Units Affected 38

Summary

Kovatch Mobile Equipment Corp. (KME) is recalling certain 2012-2016 KME Predator SS Pumper and Predator Pumper, and 2015-2016 Predator Aerial vehicles equipped with Cummins ISX12 engines. The braided cab lift hydraulic hoses, wire braided air lines and/or wire braided fuel cooler lines may be improperly routed and secured contacting the starter power stud, causing a leak and a possible short-circuit.

Remedy

KME will notify owners, and dealers will inspect the area around the starter and make sure that the hoses have sufficient clearance, replacing any damaged cab lift hydraulic hoses, and adding hose chafe guards, free of charge. The recall began on May 22, 2018. Owners may contact KME customer service at 1-800-235-3928.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

ONRD – 0005252018 – 20

TECHNICAL SERVICE BULLETIN

| Title: | Wire-Braided Cable Cab Lift Hydraulic Hose Routing | |||||||||||||||

| Date: | May 18, 2018 | |||||||||||||||

| Vehicles: | KME Custom Chassis | |||||||||||||||

| Problem: | Wire-Braided Hydraulic, Air, Cooler or Fuel Hoses may be too close to the Starter Power Stud. | |||||||||||||||

| Corrective Action: | Inspect all Wire-Braided Hoses Installed in the Starter Area for Proper Clearance, Hose Integrity,

Signs of Wear or Fraying on the Outside of any Hoses. Replace all Damaged Hoses and Install Anti-Chafing Protection for those Hoses not within the 1-inch Clearance of the Starter Power Stud (+). |

|||||||||||||||

| Work Instructions: | See Attachment. | |||||||||||||||

| Tools Required: | ||||||||||||||||

| Parts List: | As needed, order the following items necessary to complete job.

|

|||||||||||||||

| KME CONTACT: | Matt Evans, Parts Clerk, Vehicle Service | |||||||||||||||

| TELEPHONE: | 570-669-5215 | |||||||||||||||

| EMAIL: | mevans@kmefire.com | |||||||||||||||

| MAILING ADDRESS:

|

KME Fire Apparatus Plant #8 One Industrial Complex Nesquehoning, PA 18240ATTENTION: Mr. Matt Evans |

WORK INSTRUCTIONS

- If the cab is not raised, raise the cab.

Before tilting the Cab:

- Ensure the vehicle is parked on a level surface.

- The park brake is set.

- The wheels are chocked.

- All loose equipment inside the cab is removed or secure.

- Bumper equipment will not obstruct movement of cab.

- All objects are free and clear from moving cab.

- All personnel are free and clear from moving cab.

Figure 1 Cab Jack Controls

Figure 1 Cab Jack Controls

The Cab Jack Remote Controls are on a tether that is inserted into an outlet located inside the passenger cab stepwell or on the front bumper. The Lock is located on the Discharge Panel on the passenger side. There are instructional stickers on the Discharge Panel or on the inside of the Control Box. When the cab is fully up, use the safety bar lock.

To raise the cab, hold the momentary “ON” Toggle Switch “UP” and hold the black Push-button Switch “IN” until the cab is fully raised. Click the toggle switch to the “DOWN” position.

Turn the safety bar control knob counter clockwise, pull “OUT”, and turnclockwise to lock.

- Ensure that you are wearing your Person Protective Equipment before working around the battery box and vehicle.

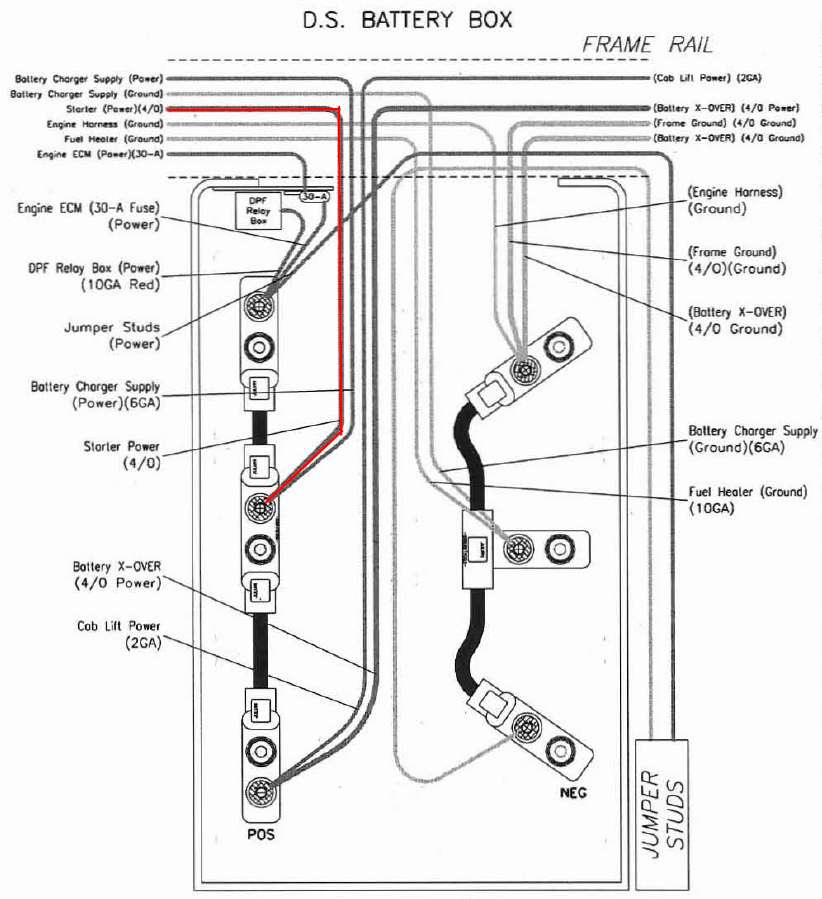

- Remove the Starter Power Wire inside the Driver Side Battery Box. See Figure 3 on next page.

Figure 3 Driver Side Battery Box Schematic

Figure 3 Driver Side Battery Box Schematic

- Locate starter on the Driver Side of the vehicle.

- Inspect the area around the starter. Ensure all lines and/or harnesses routed near the starter stud connections and cable studs have a minimum of 1-inch clearance.

A) If there is a minimum clearance of 1-inch near the starter stud connections and cable studs, no repair or anti-chafing guards (Hose Protectors) are required.

B) If there is not a minimum clearance of 1-inch near the starter stud connections and cable studs, anti-chafing guards (Hose Protectors) are required.

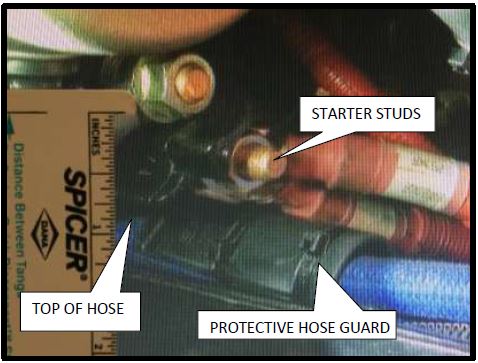

NOTE: Photo on the right illustrates how close both studs are to the top of the blue-hydraulic hose. Use the ruler to the left to see how close the wires are to the starter studs. The hose protector is already installed using nylon wire ties to secure the protector.

Figure 4 Hose Protector Installed

Figure 4 Hose Protector Installed

- Inspect the condition of the lines and/or harnesses routed near the starter stud connections and cable studs. Ensure that there is no wear or fraying on the outside of the hose, lines and harnesses.

A) If there is wear or fraying on the outside of the hose, lines and/or harnesses, replace the worn part.

B) If there is no wear or fraying on the outside of the hose, lines and/or harnesses, no repair is required.

- Report findings from Steps 5 and 6 to the KME Contact on the front page of this bulletin.

- Replace any damaged hoses, lines and harnesses. See Parts List on first page of bulletin. If no repairs needed, go to step 9.

- Vehicles with less than 1-Inch clearance must install anti-chafing protection. Determine the size of the protector and order. See Parts List and KME Contact on first page of bulletin. When the protectors arrive, continue to step 10.

- Install anti-chafing protective cover(s).

- Use nylon wire ties to bundle the cables, hoses and lines away from the starter stud connections and cable studs.

- Remove all tools and clean area.

- Reconnect the starter power wire removed inside the driver side battery box. (Refer to step 3 and Figure 3.)

- When job complete, lower cab.

NOTE: FOLLOW THE PREVIOUS WARNINGS AND CHECK THAT ALL TOOLS, OTHER OBJECTS, AND PERSONNEL ARE FREE AND CLEAR FROM THE PATH OF THE CAB.

« Ensure all safety rules are followed before lowering.«

- To lower the cab, turn the Safety Bar Control Knob counterclockwise, push-in, and turn clockwise to lock.

- Push the toggle switch “DOWN”. The cab will begin to lower.

- Leave the switch in the “DOWN” position.

May 22, 2018

Name

Street

City, State Zip

IMPORTANT SAFETY RECALL NOTICE: 18V237

IMPORTANT SAFETY RECALL

This notice applies to your vehicle(s):

Dear KME Vehicle Owner:

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act.

Why is a recall being conducted?

KME has decided that a defect which relates to motor vehicle safety exists in certain model year 2012-2016 KME vehicles manufactured from January 2012 through November 2016 built with wire braided cab lift hydraulic hoses and a Cummins ISX12 engine along with wire braided air lines and/or a fuel cooler with wire braided fuel lines.

On some vehicles with this component combination, the cab lift hydraulic hose may not have been routed or secured properly, allowing it to come into contact with the starter power stud or connected ring terminals. Over time, if the cab lift hydraulic hose comes into contact with the starter power stud or connected ring terminals, the hose may be worn causing fluid leakage and/or arcing between the starter power stud and the now exposed wire reinforcement in the hose increasing the risk of fire.

What are we doing about the problem?

A KME certified Dealer or technician will inspect the area near the starter for proper routing and clearance of the cab lift hydraulic hose, replace any damaged cab lift hydraulic hoses, and add hose chafe guards in that area where necessary at no cost to the vehicle owner. The remedy should take approximately 1.5 hours for inspection and installing chafe guards. If hose replacement is required, an additional 2 hours is estimated.

What should you do?

If you receive this notification, please contact your KME Dealer or KME Customer Service at (570) 669-5230 to schedule an appointment to have your vehicle(s) remedied.

INCLUDED WITH THIS LETTER IS AN OWNER RESPONSE CARD THAT MUST BE FILLED OUT AND RETURNED TO KME IN ORDER TO BE REIMBURSED. Please have your Truck

VIN or GSO available. After the repair has been completed, please fill in the appropriate information on the enclosed Owner Response Postcard, sign it, and return it to:

Mail: KME, One Industrial Complex, Nesquehoning, PA 18240

E-mail: bpolgrean@kmefire.com

Fax: (570) 645-9705

What if you no longer own this vehicle?

If you are not the current owner of the vehicle, please indicate this on the Owner Response Postcard and return the card to us.

Federal law requires any lessor who receives a notification of a safety related defect or noncompliance pertaining to any leased motor vehicle shall send the notice to the lessee within 10 days. If you are no longer the owner of this vehicle, please provide us with any contact information so we may contact the new owner.

If you have already paid to have your vehicle repaired for this condition, you may be eligible for reimbursement of the charges you paid for the repair or replacement of components. To learn more about what you need to do to obtain reimbursement, contact our customer service department.

If after having attempted to take advantage of this recall you believe you have not been able to have your vehicle remedied without charge and within a reasonable amount of time, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, D.C., 20590; or call the toll-free Vehicle Safety Hotline at 1888-327-4236 (TTY: 1-800-424-9153); or go to https://www.safercar.gov.

We apologize for any inconvenience this safety recall may cause, but your safety is our first concern.

Sincerely,

KME, Inc.

12 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| KME | PREDATOR AERIAL | 2015-2016 |

| KME | PREDATOR PUMPER | 2012-2016 |

| KME | PREDATOR SS PUMPER | 2012-2016 |

8 Associated Documents

Remedy Instructions and TSB

RCRIT-18V237-2718.pdf 473.697KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

Loading...

Loading...

Recall Quarterly Report #4, 2019-1

RCLQRT-18V237-5599.PDF 211.428KB

Loading...

Loading...

Recall Quarterly Report #2, 2018-3

RCLQRT-18V237-5370.PDF 214.615KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-18V237-0401.pdf 133.883KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-18V237-1482.PDF 216.849KB

Loading...

Loading...

Recall Acknowledgement

RCAK-18V237-5019.pdf 246.194KB

Loading...

Loading...

Recall Quarterly Report #3, 2018-4

RCLQRT-18V237-8287.PDF 211.329KB

Loading...

Loading...

Latest Recalls Documents

https://www-odi.nhtsa.dot.gov/acms/cs/documentList.xhtml?docId=18V237&docType=RCL

- Formulated with premium base stocks for added resistance to thermal breakdown

- Outstanding wear protection

- Excellent resistance to system rust and oil oxidation

- Maintains excellent water separating properties

- Excellent foam control and air release deliver consistent system operation

- Formulated with premium base stocks for added resistance to thermal breakdown

- Outstanding wear protection

- Excellent resistance to system rust and oil oxidation

- Maintains excellent water separating properties

- Excellent foam control and air release deliver consistent system operation

- Formulated with highly refined group ii base stocks for added resistance to thermal breakdown

- Superior wear protection to protect critical components

- Excellent frictional properties for smooth-shifting, excellent anti-shudder performance

- J20c equivalent, protection against varnish and sludge formation

- Superior thermal stability and oxidation resistance, good seal compatibility

- Meets and exceeds all OEM specifications for power shift transmissions

- Extends equipment and fluid life

- Reduces downtime and major overhaul

- Formulated with premium base stocks for added resistance to thermal breakdown

- Outstanding wear protection

- Excellent resistance to system rust and oil oxidation

- Maintains excellent water separating properties

- Excellent foam control and air release deliver consistent system operation

- Reduces the operating temperature of hydraulic systems

- Conditions old seals and O-rings to stop and prevent future leaks

- Well suited for use in equipment with wet brakes

- Removes varnish and restores pressure for more efficient operation

- Compatible with both synthetic and conventional hydraulic fluids

- MULTI-PURPOSE & ALL SEASON: A premium transmission-hydraulic fluid recommended for the complex lubrication systems of modern tractors, including industrial models. In these systems, the same lubricant may serve the hydraulic system, torque converter, transmission, power take-off, differential, power steering, and wet brakes.

- SPECIFICATIONS: Our tractor hydraulic fluid meets the following manufacturers specifications: (J20C, JD303), (Q-1826), (Improved power fluid 821XL), (ESN-M2C134-D, FNHA-2-C-201), (M1135, M1141, M1143), (Type 55), (JIC-143,144, 145, MS1206,127, 1209, 1210, TCH), (Fluids), (TO-2, MTD), (Bus Automatic Transmission Fluid), (UDT), (B6), (WB 101).

- APPLICATIONS: Included in the above applications, this universal tractor fluid also meets most other manufacturers' specifications for transmission hydraulic fluid. It can be used for makeup or refill in almost all tractor hydrostatic, hydraulic jack oil, transmission oil, differential fluid, and other systems involving common lube oil sumps.

- BENEFITS: This tractor transmission oil gives all-season protection. It flows readily at low temperatures due to its low-temperature viscosity and pour point, and yet retains its body at high temperatures due to a high viscosity index. Other benefits include anti-foam, anti-rust, anti-wear, extreme pressure, seal protection, oxidative and thermal stability, and controlled frictional characteristics.

- PREMIUM LUBRICANTS: Presidential Engineered Lubricants offers premium machine oils, lubricants, and sealants for various industries. Founded in 1877, we're an employee-owned company dedicated to crafting high-quality products at our UO facility, with customer satisfaction as our top priority.

Last update on 2024-06-10 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.